What is a butterfly type valve?

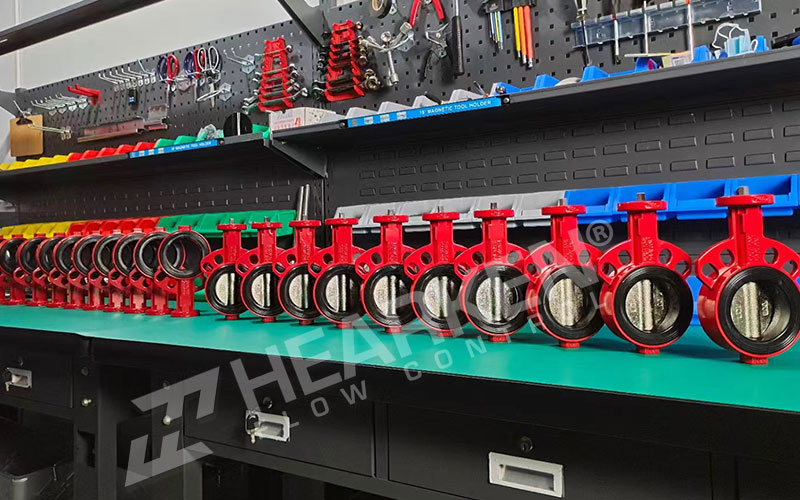

The butterfly valve is a type of valve used to regulate a medium's flow tlrough a pipeline. It is attached to the pipeline and serves as a flow control device. The butterfly valve has a straightforward design and is klnown for its low weight. Its components include a transmission device, a valve body, a valve plate, a valve stem, and a valve seat, amongst others.

The butterfly valve is the most labour-efficient form of the valve because it requires the least amount of force to open and close it, it has a high switching speed. and it is faster than other types of valves. The manu al butterfly valve is the performance that stands out the most. A buttertly valve's opening and closing mechanism consist of a disc-shaped butterfly plate that revolves around the valve stem inside the valve body. This allows the valve to open and close. To fully open the butterfly valve,it merely has to turn through 90 degrees. When the butterfly valve is completely open. the only thing determining the thickness of the mecdium in the pipeline is the thickness of the butterfly plate. Flow resistance, flow resistance is likewise not very significant at all.

So, what are the applications for butterfly valves, and what are their defining characteristics?

The use of butterfly valves is rampant, and we encounter them virtuallyconstantly in both our manufacturing and our everyday lives. In general, butterfly valves can be used with any water and a variety of other fluid media at typical temperatures and pressures. For example, our household water pipelines, fire water pipelines, circulating water pioelines, sewage pipelines, and so on can employ butterfly valves for flow control and regulation. In addition, several powders, oil, and mud meedium pipes are also suitable for butterfly valves. In addition, butterfly valves may be utilized in ventilation ductwork.

Butterfly valves are ideal for large-diameter valves than other types because they are smaller in size, lighter in weight, require less labour, and are more cost-effective under the same conditions as different types of valves. This benefit of having a butterfly valve will become more and more apparent as the caliber increases in size.

In addition, the butterfly valve can modify the flow in the pipeline; howewer, in practice. this adjustment is rarely made using the butterfly valve when the pipeline in question has a tiny diameter. Regarding regulating flow, there is a distinction between the globe valve and the ball valve.

Seals for butterfly valves can be soft or rigid, depending on the use. The functions of each of the two different kinds of butterfly valves are also different. The soft seal butterfly valve has a good sealing performancee; however, because it is not resistant to high temperature or high-pressure situations, it usually is only used for weak fluids such as water, air, oil, and so on—acid-alkaline medium. Hard-sealed butterfly valves are resistant to erosion and can be utilized in harsh situations such as high temperatures and pressures. In most cases, they are used in chemical settings, smelting operations, and other difficult situations.

Last but not least, the transmission method of the butterfly valve is distirnct, as is its application. Additionally, the use is also different. Typically, the butterfly valve equipped with an electric device or a pneumatic device is installed in some hazardous working conditions, such as high-altitude pipelines, toxic and harmful medium pipes, and other pipelineswhere manual labour is not appropriate.