3 Piece Electric Actuated Ball Valve

3 Piece Electric Actuated Ball Valve

Item Number:

The three-piece electric ball valve adopts an integrated structure and is matched with the actuator mechanism. The operation can be controlled by inputting a control signal (4~20mA or 1~5VDC) and a one-way power supply. It has strong functions, small size, reliable performance, and simple matching. Features such as large circulation capacity. Widely used in industrial automatic control systems in environmental protection, light industry, petroleum, papermaking, chemical power and other industries.

Description

The electric three-piece ball valve adopts an integrated structure and matches with the electric actuator. It can control the operation with an input control signal (4~20mADC or 1~5VDC) and a single-phase power supply. It has strong functions, is small in size, is lightweight, has Reliable performance, simple matching, and large flow capacity, especially suitable for occasions where the medium is viscous, contains particles, and is fibrous. At present, the valve is widely used in industrial automatic control systems in food, environmental protection, light industry, petroleum, papermaking, chemical industry, teaching and scientific research equipment, electric power, and other industries.

Main Product Features:

• Direct mount ISO5211 Full Port stainless steel ball valve

• 3-piece swing out body designed for easy maintenance

• 1000 PSI working pressure at 100°F (38°C)

• Visual valve position indicator

• Heavy-duty motors with overload protection

• Thermostatically controlled anti-condensation heater• Manual override with end-of-travel mechanical stops

• Two auxiliary limit switches included with on-off units

Performance Features

| Electric Actuator | Ball Valve | |||

| Function | On/OfffforModulating | Cap | CF8M,CF8,WCB | |

| Housing | Aluminum alloy, epoxy powder coated | Gasket | PTFE | R-PTFE |

| Gear | Steel/aluminum bronze | Ball Seat | PTFE | R-PTFE |

| Screws | Stainless steel | Ball | SS316 | SS304 |

| Indicator Cover | Polycarbonate | Thrust Washer | PTFE | R-PTFE |

| Shaft/Adaptor | Alloy steel | O-Ring | VITON | |

| Seal | NBR | Stem Packing | PTFE | R-PTFE |

| Lubrication | Aluminum based grease | Gland | SS304 | |

| Power Supply | 24VDC,110VAC,220VAC | Spring Washer | SS304 | |

| Motor | Squirrel cage asynchronous motor | Stop Nut | SS304 | |

| Limit Switch | SPDT,250VAC 10A, each for Open and Close positions | Stop Washer | SS304 | |

| Rotation | 90°(±10°) other rotation on request | Gland | SS304 | |

| Manual Operation | Mechanical handle standard | Handle | SS304 | SS201 |

| Conduit Entry | 2xM18 | Stem Nut | SS304 | SS201 |

| Operating Temp | -20°C to+70°C | Body | CF8M,CF8,WCB | |

| Ambient Humidity | Max.90%RH | Pin | SS201 | |

| Vibration Tested | XYZ10g,0.2~34Hz,30minutes | Anti-Static Device | SS316 | SS304 |

| Mounting | ISO5211 | Stem | SS316 | SS304 |

| Torque Output | 30Nm to1000Nm (2000Nm on request) | Locking Device | SS316 | SS304 |

| Self-locking device | Self-locking by worm and worm gear | Handle Cover | PLASTIC | |

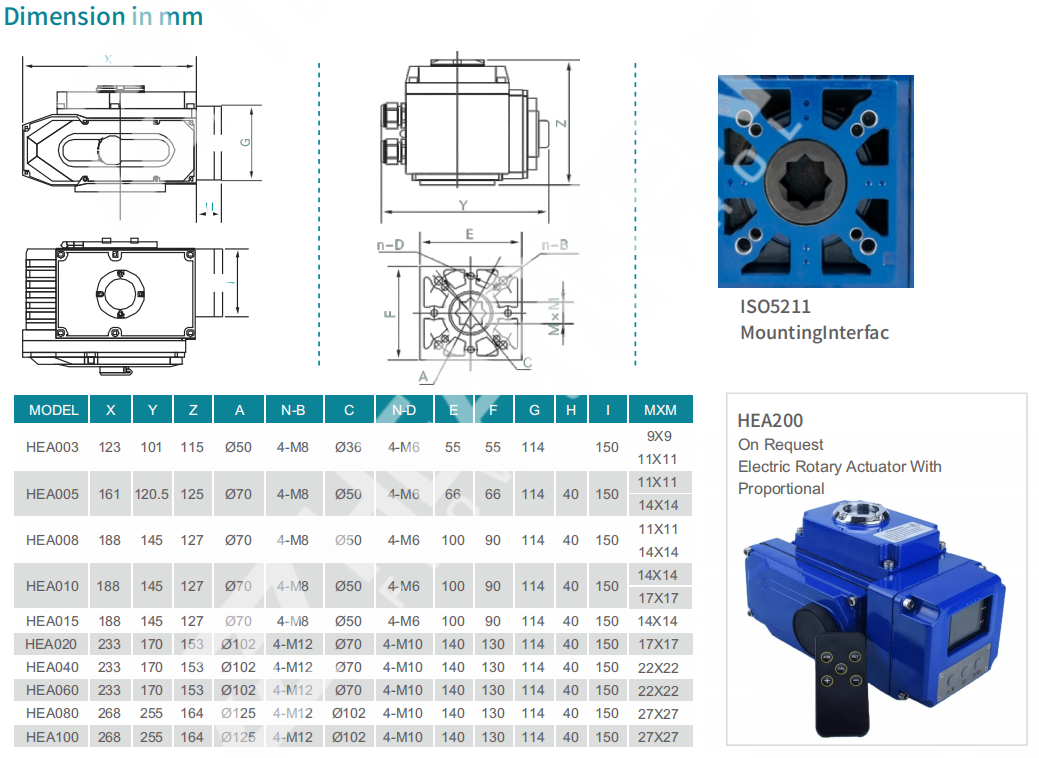

Technical Parameter and Specifications (On/Off or Modulating Version)

| Model | Max Output Torque(N.M) | Operating Time 90°(Sec.) 220VAC/24VDC | Drive Shaft(mm) |

Motor(W) 220V/24VDC | Single-phsae rated current(A) 220VAC/24VDC | Weight(kg) | |||

| Square | Deep | Round | Deep | ||||||

| HEA003 | 30N.m | 10/10 | 9X9 | 13.5 | Ø12.6 | 26 | 8 | 0.3/2 | 2.1 |

| 11X11 | 15.5 | ||||||||

| HEA005 | 50N.m | 30/15 | 11X11 | 15.5 | Ø12.6 | 26 | 10 | 0.24/2.4 | 3.6 |

| 14X14 | 18 | ||||||||

| HEA008 | 80N.m | 30/15 | 11X11 | 15.5 | Ø15.78 | 26 | 10 | 0.25/2.5 | 3.6 |

| 14X14 | 18 | ||||||||

| HEA010 | 100N.m | 30/15 | 14X14 | 18 | Ø15.78 | 28 | 15 | 0.35/3.5 | 4.6 |

| 17X17 | 22.5 | Ø18.95 | |||||||

| HEA015 | 150N.m | 30/15 | 14X14 | 18 | Ø18.95 | 28 | 15 | 0.37/3.5 | 4.6 |

| 17X17 | 22.5 | ||||||||

| HEA020 | 200N.m | 30/15 | 22X22 | 26 | Ø22.13 | 45 | 45 | 0.48/6 | 8.9 |

| HEA040 | 400N.m | 30/15 | 22X22 | 26 | Ø28.48 | 45 | 60 | 0.5/6 | 8.9 |

| HEA060 | 600N.m | 30/15 | 27X27 | 32.5 | Ø31.65 | 45 | 90 | 0.92/9 | 9.9 |

| HEA080 | 800N.m | 45/22 | 27X27 | 32.5 | Ø31.65 | 45 | 180 | 1/12 | 14.3 |

| HEA100 | 1000N.m | 45/22 | 27X27 | 32.5 | Ø31.65 | 45 | 180 | 1/12 | 14.5 |

| HEA200 | 2000N.m | 45/22 | 27X27 | 32.5 | Ø31.65 | 45 | 200 | 1.5/15 | 14.5 |