Heavy Duty Pneumatic Actuator

Heavy Duty Pneumatic Actuator

Item Number: HPA-G

Designed for demanding applications, the HPA-G Heavy Duty Pneumatic Actuator delivers up to 270,000 Nm of torque with IP67 protection and ISO 5211 compatibility. Featuring a modular design, superior corrosion resistance, and safety-optimized spring modules, it ensures reliable performance in harsh environments. Ideal for large-diameter valves and 90° rotary applications.

Product Characteristics

NAMUR Mounting

The accessory mounting holes of HPA-G series pneumatic actuators are in accordance with NUMAR standard, which is convenient for mounting position switches, positioners and other accessories.

1. IP67 Protection Rate

HPA-G series pneumatic actuators are equipped with high-qualitysealing rings in the connecting parts such as box body and boxcover, and the protection level can reach lP67, which can workcontinuously and stably in harsh environment and climate.

2. ISO Connection Dimension

The fange size of HPA-G series pneumatic actuators and valvesmeets lS0 5211 intemational standard, which is convenient forcustomers to install, disassemble and replace.

3. Internal Tie Rod Cylinder Design

The cylinder with internal pull rod design is simple andgenerous in shape. Under the same cylinder diameter, theouter diameter of the cylinder with internal pull rod design issmaller than that with external pull rod design. At the sametime, the pull rod inside the cylinder can support and guidethe piston to prevent the cylinder from eccentric wear, so asto make the action more stable and prolong the service life.

4. Security Spring Module

The spring module is fixed into an integral form afterthe spring is compressed, which improves theoperation convenience and safety when installing andmaintaining the spring module.

5. Large Torque Range

The HPA-G Series double-acting actuators provide a torque outputof up to 270000 Nm, and the single-acting actuators provide atorque output of up to 120000 Nm (operating pressure 3-7 bar).

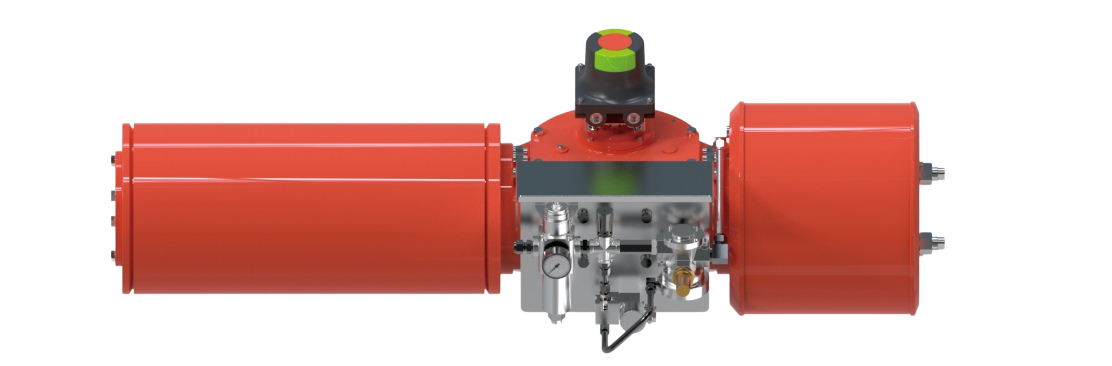

6. Modular Design

HPA-G series pneumatic actuators can be divided intodrive module, cylinder module, spring cylinder module,manual device and other independent modules,which can be installed and maintained according tocustomers" individual needs.

7. Protection Coat

Shot blasting and grinding before spraying make the surfaceof the product smoother and fatter. HPA-G series actuators aresprayed with epoxy zinc-rich primer and polyurethanetopcoat, and the coating thickness, firmness andanticorrosion performance meet the requirements of differentharsh environments.

Working Technical Conditions

| Travel Adjustment Range | The two independent external travel stop adjustment bolts can adjust ± 6at both open and close directions easily and precisely. | |

| Working Air Supply Pressure | 0.3Mpa-0.7Mpa(Special working pressure 0.2Mpa-1.0Mpa) | |

| Operating Temperature | Standard | -20℃~+80℃ |

| High Temperature | -20℃~+200℃ | |

| Low Temperature | -40℃~+80℃ | |

| Application Range | The characteristics of U type curve output torque of HPA-G pneumatic actuators are generally applicable to the switch and adjustment of large-diameter ball valves, butterfly valves and plug valves as well as used in other 90° rotary applications. | |

| Automatic Control Formula | Hearken has many years of experience in pneumatic control. lt can designvarious pneumatic connection formulas according to customer needs andselect proper control accessories to meet the requirements of users. | |

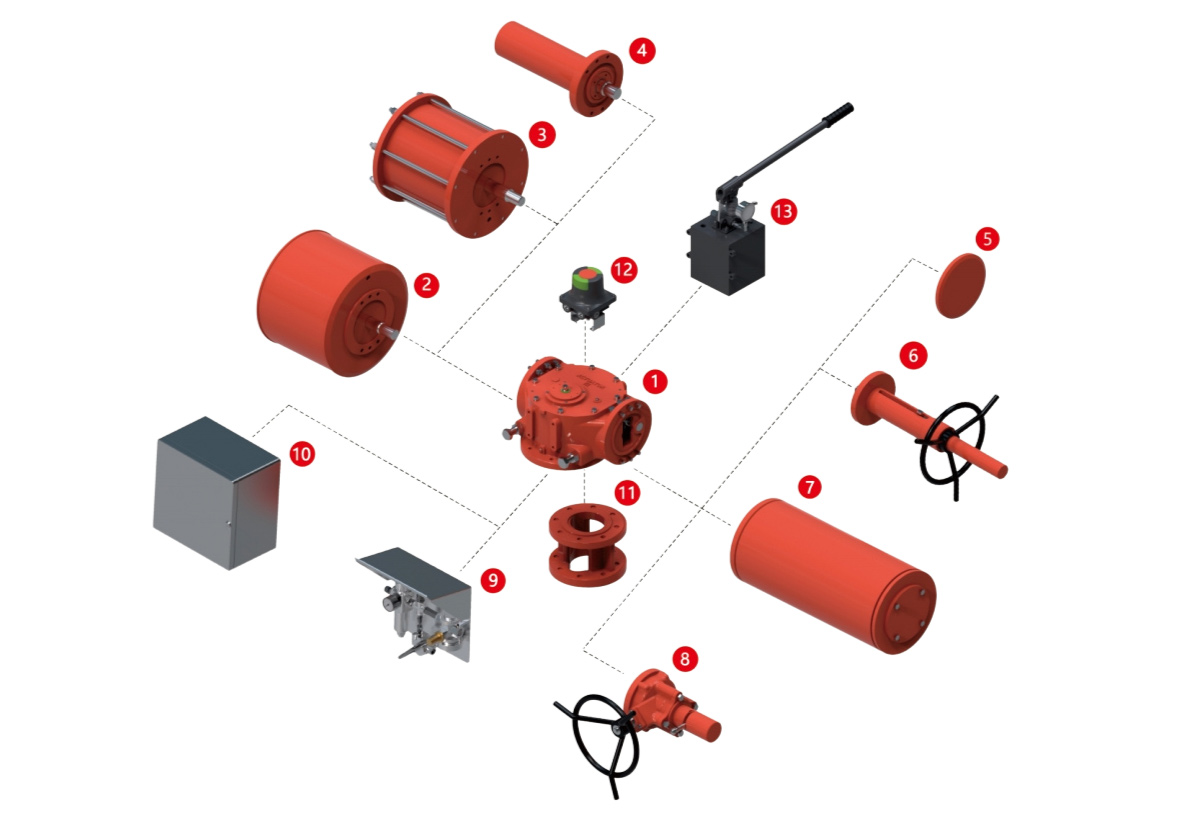

Multi-Function Modules

Drive Module:

1. The materials of the box body and the fork are ductile iron, which has better corrosion resistance,wear resistance and hiah separation:

2.The limiting device can provide angle adjustment of +6°;

3.lt can provide torque output of up to 270000Nm;

4. Have a variety of sealing methods, and choose high-quality and high-performance seals to ensure that internal parts are not corroded and improve their service life.

Cylinder Module:

1. The cylinder is seamless steel pipe and ground, and the inner wall ofthe cylinder is plated with hard chromium or Teflon coating and polishedwhich has anti-corrosion, anti-rust and high wear resistance andprolongs the service life of the cylinder;

2. The piston rod is made of alloy steel, with chrome plating and mirrortreatment, which is anticorrosive; Rust prevention and high wear resistance;

3. The overall cylinder design makes the cylinder very safe under highpressure;

4. The inner surface of the cylinder is coated with high-performance grease, which can self-lubricate, thus reducing friction loss and cylinder service life.

Spring Module:

1. After tensile test and fatigue test, the life of the spring can reach500,000 times,and the surface is anticorrosive and antirust;

2.The sealing welding design structure enhances the operation safety;

3.Epoxy coating provides continuous anti-corrosion performance forprestressed spring;

4. The steel spring seat is completely isolated from the externalenvironment;

5. A hydraulic module can be added inside to provide a variety of manual control modes.

| NO. | 01 | 02 | 03 | 04 | 05 | 06 | 07 |

| Description | Drive Module | Cylinder Module | Cylinder Module | Hydraulic Cylinder Module | Capping | Screw Manual | Spring Module |

| NO. | 08 | 09 | 10 | 11 | 12 | 13 | |

| Description | Bevel Gear Manual | Pneumatic Accessories | Junction Box | Bracket | Limit Switch | Hydraulic Manual |

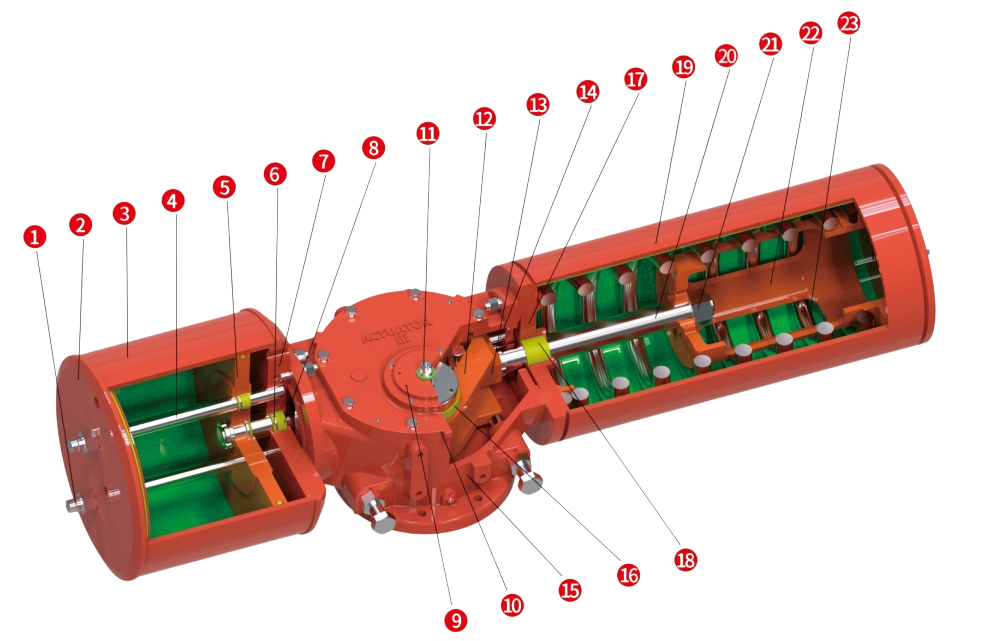

Product Structures

| Cylinder Module | ||||||||

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| Description | Nut (component) | Outer Cover | Cylinder | Rod | Piston | Piston Rod | Middle Cover | Support Ring |

| Material | Carbon Steel | Carbon Steel | Carbon Steel | Alloy steel | Carbon Steel | Alloy Steel | Carbon Steel | Synthetic Resin |

| Drive Module | ||||||||

| No. | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| Description | Bonnet | Body Cover | Indicator Axis | Yoke | Guide Block | Guide Rod | Centre Body | Oilless Bearing |

| Material | Carbon Steel | Ductile lron | Stainless steel | Ductile lron | Alloy Steel | Alloy Steel | Ductile lron | Composite Material |

| Spring Module | ||||||||

| No. | 17 | 18 | 19 | 20 | 21 | 22 | 23 | |

| Description | Flange Cap | Oilless Bearing | Spring Body | Spring Rod | Nut | Spring Seat | Spring | |

| Material | Carbon Steel | Composite Material | Carbon Steel | Alloy Steel | Carbon Steel | Carbon Steel | Spring Steel | |

Output Torque of Double Acting Actuator

| Model | 0.5Mpa Double acting output torque(N.m) | |||||||||||||||||||||||||||||||

| 0.4Mpa | 0.5Mpa | 0.6Mpa | ||||||||||||||||||||||||||||||

| Start End |

45° Running |

Start End |

45° Running |

Start End |

45° Running |

|||||||||||||||||||||||||||

| HPA-G1-250DA | 2069 | 1119 | 2587 | 1398 | 3104 | 1678 | ||||||||||||||||||||||||||

| HPA-G1-280DA | 2596 | 1403 | 3245 | 1754 | 3894 | 2105 | ||||||||||||||||||||||||||

| HPA-G1-300DA | 2980 | 1611 | 3725 | 2014 | 4470 | 2416 | ||||||||||||||||||||||||||

| HPA-G2-250DA | 2587 | 1398 | 3234 | 1748 | 3880 | 2097 | ||||||||||||||||||||||||||

| HPA-G2-300DA | 3725 | 2014 | 4656 | 2517 | 5588 | 3020 | ||||||||||||||||||||||||||

| HPA-G2-350DA | 5070 | 2741 | 6338 | 3426 | 7605 | 4111 | ||||||||||||||||||||||||||

| HPA-G3-350DA | 6084 | 3289 | 7605 | 4111 | 9126 | 4933 | ||||||||||||||||||||||||||

| HPA-G3-400DA | 7947 | 4296 | 9933 | 5369 | 11920 | 6443 | ||||||||||||||||||||||||||

| HPA-G3-450DA | 10058 | 5437 | 12572 | 6796 | 15086 | 8155 | ||||||||||||||||||||||||||

| HPA-G4-450DA | 12293 | 6645 | 15366 | 8306 | 18439 | 9967 | ||||||||||||||||||||||||||

| HPA-G4-500DA | 15176 | 8203 | 18970 | 10254 | 22764 | 12305 | ||||||||||||||||||||||||||

| HPA-G4-550DA | 18363 | 9926 | 22954 | 12407 | 27544 | 14889 | ||||||||||||||||||||||||||

| HPA-G5-550DA | 23371 | 12633 | 29214 | 15791 | 35057 | 18950 | ||||||||||||||||||||||||||

| HPA-G5-600DA | 27813 | 15034 | 34767 | 18793 | 41720 | 22551 | ||||||||||||||||||||||||||

| HPA-G5-700DA | 37857 | 20463 | 47322 | 25579 | 56786 | 30695 | ||||||||||||||||||||||||||

| HPA-G6-600DA | 33774 | 18256 | 42217 | 22820 | 50660 | 27384 | ||||||||||||||||||||||||||

| HPA-G6-700DA | 45970 | 24848 | 57462 | 31060 | 68954 | 37273 | ||||||||||||||||||||||||||

| HPA-G6-800DA | 60042 | 32455 | 75052 | 40569 | 90063 | 48683 | ||||||||||||||||||||||||||

| HPA-G7-800DA | 74169 | 40092 | 92712 | 50114 | 111254 | 60137 | ||||||||||||||||||||||||||

| HPA-G7-900DA | 93871 | 50741 | 117338 | 63426 | 140806 | 76111 | ||||||||||||||||||||||||||

| HPA-G7-1000DA | 115890 | 62643 | 144862 | 78304 | 173834 | 93965 | ||||||||||||||||||||||||||

| HPA-G8-900DA | 120691 | 65238 | 150863 | 81548 | 181036 | 97857 | ||||||||||||||||||||||||||

| HPA-G8-1000DA | 149001 | 80541 | 186251 | 100676 | 223501 | 120812 | ||||||||||||||||||||||||||

| HPA-G8-1100DA | 180291 | 97455 | 225364 | 121818 | 270437 | 146182 | ||||||||||||||||||||||||||

Single-acting Actuator Output Torque

| Model | 0.6Mpa Single acting output torque(N.m) | |||||||||||||||||||||||||||||||||

| Spring output torque | Cylinder output torque | |||||||||||||||||||||||||||||||||

| 0° | 45° | 90° | 0° | 45° | 90° | |||||||||||||||||||||||||||||

| HPA-G1-250SR | 807 | 574 | 1211 | 1262 | 545 | 859 | ||||||||||||||||||||||||||||

| HPA-G1-280SR | 1012 | 720 | 1519 | 1584 | 684 | 1077 | ||||||||||||||||||||||||||||

| HPA-G1-300SR | 1162 | 826 | 1743 | 1818 | 785 | 1237 | ||||||||||||||||||||||||||||

| HPA-G2-250SR | 1009 | 717 | 1513 | 1578 | 681 | 1074 | ||||||||||||||||||||||||||||

| HPA-G2-300SR | 1453 | 1033 | 2179 | 2272 | 981 | 1546 | ||||||||||||||||||||||||||||

| HPA-G2-350SR | 1977 | 1405 | 2966 | 3093 | 1335 | 2104 | ||||||||||||||||||||||||||||

| HPA-G3-350SR | 2373 | 1687 | 3559 | 3711 | 1602 | 2525 | ||||||||||||||||||||||||||||

| HPA-G3-400SR | 3099 | 2203 | 4649 | 4847 | 2093 | 3298 | ||||||||||||||||||||||||||||

| HPA-G3-450SR | 3922 | 2788 | 5884 | 6135 | 2649 | 4174 | ||||||||||||||||||||||||||||

| HPA-G4-450SR | 4794 | 3408 | 7191 | 7498 | 3237 | 5101 | ||||||||||||||||||||||||||||

| HPA-G4-500SR | 5919 | 4207 | 8878 | 9257 | 3996 | 6298 | ||||||||||||||||||||||||||||

| HPA-G4-550SR | 7162 | 5090 | 10742 | 11201 | 4836 | 7621 | ||||||||||||||||||||||||||||

| HPA-G5-550SR | 9115 | 6478 | 13672 | 14256 | 6155 | 9699 | ||||||||||||||||||||||||||||

| HPA-G5-600SR | 10847 | 7710 | 16271 | 16966 | 7324 | 11543 | ||||||||||||||||||||||||||||

| HPA-G5-700SR | 14764 | 10494 | 22146 | 23093 | 9969 | 15711 | ||||||||||||||||||||||||||||

| HPA-G6-600SR | 13172 | 9362 | 19758 | 20602 | 8894 | 14016 | ||||||||||||||||||||||||||||

| HPA-G6-700SR | 17928 | 12743 | 26892 | 28041 | 12106 | 19077 | ||||||||||||||||||||||||||||

| HPA-G6-800SR | 23416 | 16644 | 35124 | 36626 | 15811 | 24917 | ||||||||||||||||||||||||||||

| HPA-G7-800SR | 28926 | 20560 | 43389 | 45243 | 19532 | 30780 | ||||||||||||||||||||||||||||

| HPA-G7-900SR | 36610 | 26021 | 54914 | 57261 | 24720 | 38956 | ||||||||||||||||||||||||||||

| HPA-G7-1000SR | 45197 | 32125 | 67795 | 70693 | 30518 | 48094 | ||||||||||||||||||||||||||||

| HPA-G8-900SR | 47069 | 33455 | 70604 | 73621 | 31783 | 50087 | ||||||||||||||||||||||||||||

| HPA-G8-1000SR | 58110 | 41303 | 87165 | 90891 | 39238 | 61835 | ||||||||||||||||||||||||||||

| HPA-G8-1100SR | 70314 | 49977 | 105470 | 109978 | 47478 | 74821 | ||||||||||||||||||||||||||||

| Model | 0.5Mpa Single acting output torque(N.m) | |||||||||||||||||||||||||||||||

| Spring output torque | Cylinder output torque | |||||||||||||||||||||||||||||||

| 0° | 45° | 90° | 0° | 45° | 90° | |||||||||||||||||||||||||||

| HPA-G1-250SR | 1009 | 717 | 1513 | 1578 | 681 | 1074 | ||||||||||||||||||||||||||

| HPA-G1-280SR | 1266 | 899 | 1898 | 1979 | 855 | 1347 | ||||||||||||||||||||||||||

| HPA-G1-300SR | 1453 | 1033 | 2179 | 2272 | 981 | 1546 | ||||||||||||||||||||||||||

| HPA-G2-250SR | 1261 | 896 | 1892 | 1972 | 852 | 1342 | ||||||||||||||||||||||||||

| HPA-G2-300SR | 1816 | 1291 | 2724 | 2840 | 1226 | 1932 | ||||||||||||||||||||||||||

| HPA-G2-350SR | 2472 | 1757 | 3708 | 3866 | 1669 | 2630 | ||||||||||||||||||||||||||

| HPA-G3-350SR | 2966 | 2108 | 4449 | 4639 | 2003 | 3156 | ||||||||||||||||||||||||||

| HPA-G3-400SR | 3874 | 2754 | 5811 | 6059 | 2616 | 4122 | ||||||||||||||||||||||||||

| HPA-G3-450SR | 4903 | 3485 | 7355 | 7669 | 3311 | 5217 | ||||||||||||||||||||||||||

| HPA-G4-450SR | 5993 | 4259 | 8989 | 9373 | 4046 | 6377 | ||||||||||||||||||||||||||

| HPA-G4-500SR | 7398 | 5258 | 11097 | 11572 | 4996 | 7873 | ||||||||||||||||||||||||||

| HPA-G4-550SR | 8952 | 6363 | 13428 | 14002 | 6045 | 9526 | ||||||||||||||||||||||||||

| HPA-G5-550SR | 11393 | 8098 | 17090 | 17820 | 7693 | 12124 | ||||||||||||||||||||||||||

| HPA-G5-600SR | 13559 | 9637 | 20339 | 21208 | 9156 | 14428 | ||||||||||||||||||||||||||

| HPA-G5-700SR | 18455 | 13118 | 27683 | 28866 | 12462 | 19638 | ||||||||||||||||||||||||||

| HPA-G6-600SR | 16465 | 11703 | 24697 | 25752 | 11117 | 17520 | ||||||||||||||||||||||||||

| HPA-G6-700SR | 22410 | 15928 | 33615 | 35052 | 15132 | 23847 | ||||||||||||||||||||||||||

| HPA-G6-800SR | 29270 | 20805 | 43906 | 45782 | 19764 | 31147 | ||||||||||||||||||||||||||

| HPA-G7-800SR | 36158 | 25700 | 54236 | 56554 | 24415 | 38475 | ||||||||||||||||||||||||||

| HPA-G7-900SR | 45762 | 32526 | 68643 | 71576 | 30900 | 48695 | ||||||||||||||||||||||||||

| HPA-G7-1000SR | 56496 | 40156 | 84744 | 88366 | 38148 | 60118 | ||||||||||||||||||||||||||

| HPA-G8-900SR | 58837 | 41819 | 88255 | 92027 | 39728 | 62608 | ||||||||||||||||||||||||||

| HPA-G8-1000SR | 72638 | 51629 | 108957 | 113613 | 49047 | 77294 | ||||||||||||||||||||||||||

| HPA-G8-1100SR | 87892 | 62471 | 131838 | 137472 | 59347 | 93526 | ||||||||||||||||||||||||||

| Model | 0.6Mpa Single acting output torque(N.m) | |||||||||||||||||||||||||||||||||

| Spring output torque | Cylinder output torque | |||||||||||||||||||||||||||||||||

| 0° | 45° | 90° | 0° | 45° | 90° | |||||||||||||||||||||||||||||

| HPA-G1-250SR | 1211 | 860 | 1816 | 1894 | 817 | 1211 | ||||||||||||||||||||||||||||

| HPA-G1-280SR | 1519 | 1079 | 2278 | 2375 | 1025 | 1519 | ||||||||||||||||||||||||||||

| HPA-G1-300SR | 1743 | 1239 | 2615 | 2727 | 1177 | 1743 | ||||||||||||||||||||||||||||

| HPA-G2-250SR | 1513 | 1076 | 2270 | 2367 | 1022 | 1513 | ||||||||||||||||||||||||||||

| HPA-G2-300SR | 2179 | 1549 | 3269 | 3408 | 1471 | 2179 | ||||||||||||||||||||||||||||

| HPA-G2-350SR | 2966 | 2108 | 4449 | 4639 | 2003 | 2966 | ||||||||||||||||||||||||||||

| HPA-G3-350SR | 3559 | 2530 | 5339 | 5567 | 2403 | 3559 | ||||||||||||||||||||||||||||

| HPA-G3-400SR | 4649 | 3304 | 6973 | 7271 | 3139 | 4649 | ||||||||||||||||||||||||||||

| HPA-G3-450SR | 5884 | 4182 | 8826 | 9203 | 3973 | 5884 | ||||||||||||||||||||||||||||

| HPA-G4-450SR | 7191 | 5111 | 10787 | 11248 | 4856 | 7191 | ||||||||||||||||||||||||||||

| HPA-G4-500SR | 8878 | 6310 | 13317 | 13886 | 5995 | 8878 | ||||||||||||||||||||||||||||

| HPA-G4-550SR | 10742 | 7635 | 16114 | 16802 | 7254 | 10742 | ||||||||||||||||||||||||||||

| HPA-G5-550SR | 13672 | 9718 | 20508 | 21385 | 9232 | 13672 | ||||||||||||||||||||||||||||

| HPA-G5-600SR | 16271 | 11565 | 24406 | 25449 | 10987 | 16271 | ||||||||||||||||||||||||||||

| HPA-G5-700SR | 22146 | 15741 | 33220 | 34639 | 14954 | 22146 | ||||||||||||||||||||||||||||

| HPA-G6-600SR | 19758 | 14043 | 29636 | 30903 | 13341 | 19758 | ||||||||||||||||||||||||||||

| HPA-G6-700SR | 26892 | 19114 | 40338 | 42062 | 18158 | 26892 | ||||||||||||||||||||||||||||

| HPA-G6-800SR | 35124 | 24965 | 52687 | 54938 | 23717 | 35124 | ||||||||||||||||||||||||||||

| HPA-G7-800SR | 43389 | 30840 | 65084 | 67865 | 29298 | 43389 | ||||||||||||||||||||||||||||

| HPA-G7-900SR | 54914 | 39031 | 82371 | 85892 | 37080 | 54914 | ||||||||||||||||||||||||||||

| HPA-G7-1000SR | 67795 | 48187 | 101693 | 106039 | 45778 | 67795 | ||||||||||||||||||||||||||||

| HPA-G8-900SR | 70604 | 50183 | 105906 | 110432 | 47674 | 70604 | ||||||||||||||||||||||||||||

| HPA-G8-1000SR | 87165 | 61955 | 130748 | 136336 | 58857 | 87165 | ||||||||||||||||||||||||||||

| HPA-G8-1100SR | 105470 | 74965 | 158205 | 164966 | 71217 | 105470 | ||||||||||||||||||||||||||||

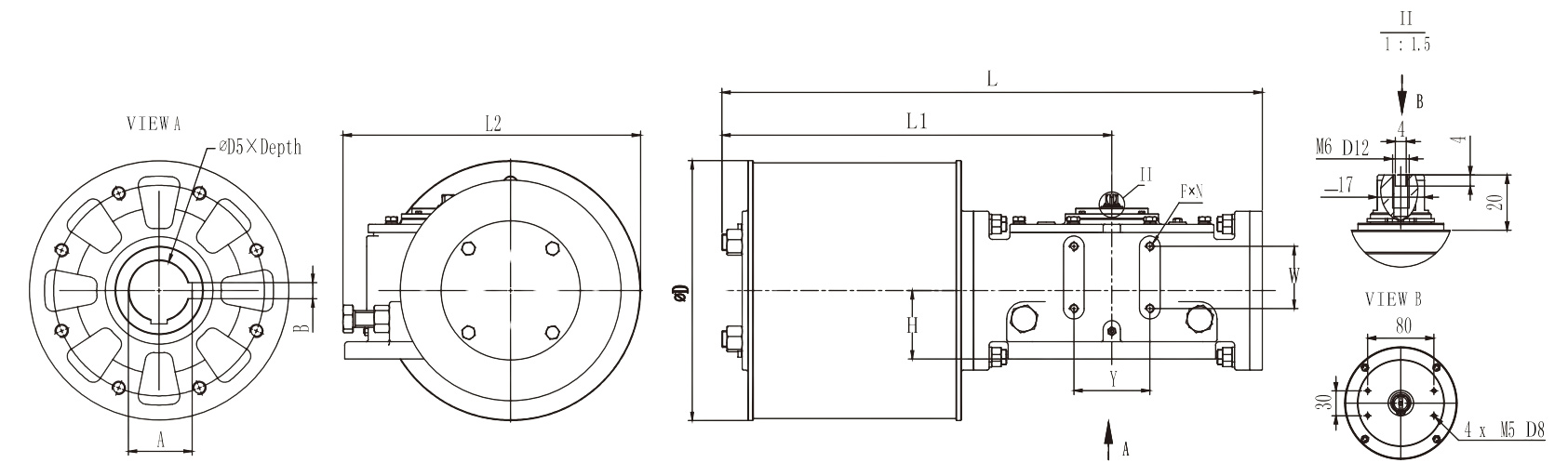

Double Acting Actuator Dimensions

| Model | L1 | L2 | H | D | E | D5×Depth | A | B | w | F×N | Connecting Flange |

Air Connection | ||||||||||||||||||||

| mm | G/NPT | |||||||||||||||||||||||||||||||

| HPA-G1-250DA | 584 | 415 | 307 | 84 | 272 | 200 | 36*70 | 39.3 | 12 | 90 | 90 | 8×M10 | F14 | 1/2" 1/2" 1/2" |

||||||||||||||||||

| HPA-G1-280DA | 594 | 425 | 317 | 84 | 294 | 213 | 42*70 | 45.3 | 12 | 90 | 90 | 8×M10 | ||||||||||||||||||||

| HPA-G1-300DA | 605 | 436 | 333 | 84 | 326 | 266 | 48*70 | 51.8 | 14 | 90 | 90 | 8×M10 | ||||||||||||||||||||

| HPA-G2-250DA | 661 | 477 | 339 | 96 | 272 | 233 | 48*100 | 51.8 | 14 | 90 | 80 | 8×M10 | F16 | 1/2" | ||||||||||||||||||

| HPA-G2-300DA | 672 | 488 | 365 | 96 | 326 | 274 | 60*100 | 64.4 | 18 | 90 | 80 | 8×M10 | 1/2" | |||||||||||||||||||

| HPA-G2-350DA | 683 | 499 | 391 | 96 | 376 | 320 | 60*100 | 64.4 | 18 | 90 | 80 | 8×M10 | 1/2" | |||||||||||||||||||

| HPA-G3-350DA | 780.5 | 564 | 43 | 99 | 376 | 320 | 60*110 | 64.4 | 18 | 110 | 90 | 8×M12 | F25 | 1/2" | ||||||||||||||||||

| HPA-G3-400DA | 795 | 578 | 455 | 99 | 426 | 340 | 72*110 | 76.9 | 20 | 110 | 90 | 8×M12 | 3/4" | |||||||||||||||||||

| HPA-G3-450DA | 795 | 578 | 479 | 99 | 476 | 370 | 72*110 | 76.9 | 20 | 110 | 90 | 8×M12 | 3/4" | |||||||||||||||||||

| HPA-G4-450DA | 920 | 668 | 522 | 125 | 476 | 370 | 72*110 | 76.9 | 20 | 130 | 110 | 8×M12 | F30 | 3/4" | ||||||||||||||||||

| HPA-G4-500DA | 930 | 678 | 550 | 125 | 526 | 420 | 98*130 | 104.4 | 28 | 130 | 110 | 8×M12 | 3/4° | |||||||||||||||||||

| HPA-G4-550DA | 930 | 678 | 575 | 125 | 576 | 440 | 98*130 | 104.4 | 28 | 130 | 110 | 8×M12 | 3/4" | |||||||||||||||||||

| HPA-G5-500DA | 1156 | 833 | 637 | 145 | 576 | 440 | 98*180 | 104.4 | 28 | 120 | 70 | 8×M12 | F35 | 3/4" | ||||||||||||||||||

| HPA-G5-600DA | 1156 | 833 | 663 | 145 | 632 | 470 | 120*180 | 127.4 | 32 | 120 | 70 | 8×M12 | 3/4" | |||||||||||||||||||

| HPA-G5-700DA | 1215 | 892 | 715 | 145 | 736 | 590 | 120*180 | 127.4 | 32 | 120 | 70 | 8×M12 | 3/4" | |||||||||||||||||||

| HPA-G6-600DA | 1425 | 1032 | 802 | 175 | 632 | 470 | 120*200 | 127.4 | 40 | 120 | 70 | 8×M12 | F40 | 1 | ||||||||||||||||||

| HPA-G6-700DA | 1454 | 1062 | 852 | 175 | 736 | 530 | 160*200 | 169.4 | 40 | 120 | 70 | 8×M12 | 1 | |||||||||||||||||||

| HPA-G6-800DA | 1500 | 1120 | 902 | 175 | 856 | 545 | 160*200 | 169.4 | 45 | 120 | 70 | 8×M12 | 1 | |||||||||||||||||||

| HPA-G7-800DA | 1698 | 1251 | 919 | 210 | 856 | 560 | 200*250 | 210.4 | 45 | 120 | 70 | 8×M12 | F48 | 1 | ||||||||||||||||||

| HPA-G7-900DA | 1698 | 1257 | 1003 | 210 | 958 | 570 | 200*250 | 210.4 | 50 | 120 | 70 | 8xM12 | 1 | |||||||||||||||||||

| HPA-G7-1000DA | 1718 | 1277 | 1057 | 210 | 1068 | 590 | 200*250 | 231.4 | 50 | 120 | 70 | 8×M12 | 1 | |||||||||||||||||||

| HPA-G8-900DA | 1838 | 1235 | 904 | 265 | 956 | 650 | 220*300 | 231.4 | 50 | 120 | 70 | 8×M12 | F60 | 1-1/4" | ||||||||||||||||||

| HPA-G8-1000DA | 1875 | 1372 | 1058 | 265 | 1068 | 660 | 220*300 | 231.4 | 50 | 120 | 70 | 8×M12 | 1-1/4" 1-1/4" |

|||||||||||||||||||

| HPA-G8-1100DA | 1890 | 1392 | 1092 | 265 | 1175 | 690 | 220*300 | 292.4 | 63 | 120 | 70 | 8×M12 | ||||||||||||||||||||

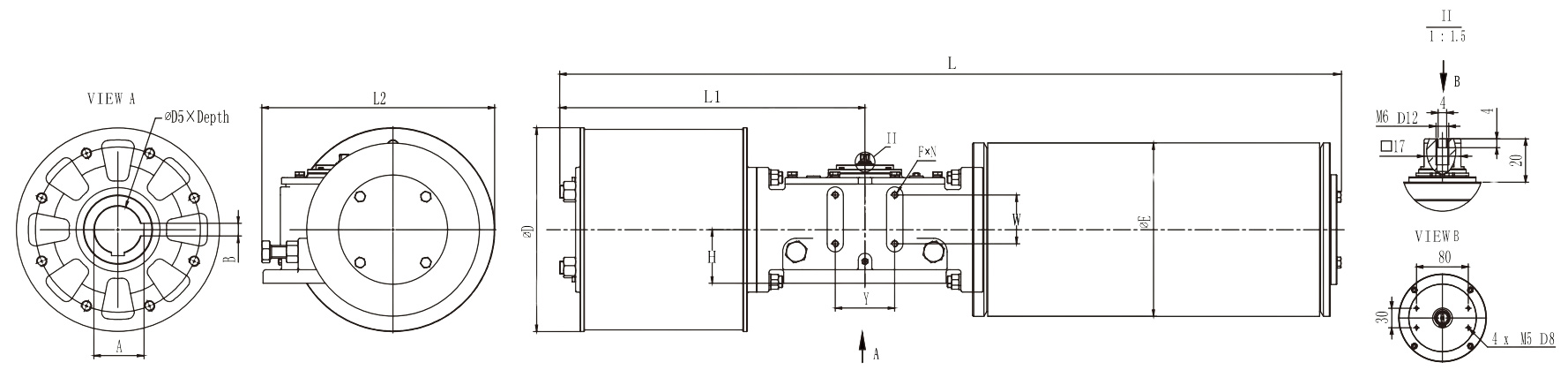

| Model | L1 | L2 | H | D | E | D5×Depth | A | B | w | FxN | Connecting Flange |

Air Connection | |||||||||||||||||||||

| mm | G/NPT | ||||||||||||||||||||||||||||||||

| HPA-G1-250SR | 1003 | 415 | 307 | 84 | 272 | 200 | 36*70 | 39.3 | 12 | 90 | 90 | 8×M10 | F14 F16 |

1/2 | |||||||||||||||||||

| HPA-G1-280SR | 1104 | 425 | 317 | 84 | 294 | 213 | 42*70 | 45.3 | 12 | 90 | 90 | 8×M10 | 1/2 | ||||||||||||||||||||

| HPA-G1-300SR | 1120 | 436 | 333 | 84 | 326 | 266 | 48*70 | 51.8 | 14 | 90 | 90 | 8×M10 | 1/2" | ||||||||||||||||||||

| HPA-G2-250SR | 1258 | 477 | 339 | 96 | 272 | 233 | 48*100 | 51.8 | 14 | 90 | 80 | 8×M10 | 1/2 | ||||||||||||||||||||

| HPA-G2-300SR | 1370 | 488 | 365 | 96 | 326 | 274 | 60*100 | 64.4 | 18 | 90 | 80 | 8×M10 | 1/2 | ||||||||||||||||||||

| HPA-G2-350SR | 1280 | 499 | 391 | 96 | 376 | 320 | 60*100 | 64.4 | 18 | 90 | 80 | 8×M10 | 1/2 | ||||||||||||||||||||

| HPA-G3-350SR | 1459 | 564 | 431 | 99 | 376 | 320 | 60*110 | 64.4 | 18 | 110 | 90 | 8×M12 | F25 | 1/2 | |||||||||||||||||||

| HPA-G3-400SR | 1488 | 578 | 455 | 99 | 426 | 340 | 72*110 | 76.9 | 20 | 110 | 90 | 8×M12 | 3/4° | ||||||||||||||||||||

| HPA-G3-450SR | 1564 | 578 | 479 | 99 | 476 | 370 | 72*110 | 76.9 | 20 | 110 | 90 | 8×M12 | 3/4° | ||||||||||||||||||||

| HPA-G4-450SR | 1703 | 668 | 522 | 125 | 476 | 370 | 72*110 | 76.9 | 20 | 130 | 110 | 8×M12 | F30 | 3/4° | |||||||||||||||||||

| HPA-G4-500SR | 1714 | 678 | 550 | 125 | 526 | 420 | 98*130 | 104.4 | 28 | 130 | 110 | 8×M12 | 3/4° | ||||||||||||||||||||

| HPA-G4-550SR | 1744 | 678 | 575 | 125 | 576 | 440 | 98*130 | 04.4 | 28 | 130 | 110 | 8×M12 | 3/4 | ||||||||||||||||||||

| HPA-G5-500SR | 2267 | 833 | 637 | 145 | 576 | 440 | 98*180 | 104.4 | 28 | 120 | 70 | 8×M12 | F35 | 3/4° | |||||||||||||||||||

| HPA-G5-600SR | 2274 | 833 | 663 | 145 | 632 | 470 | 120*180 | 127.4 | 32 | 120 | 70 | 8×M12 | 3/4 | ||||||||||||||||||||

| HPA-G5-700SR | 2625 | 892 | 715 | 145 | 736 | 590 | 120*180 | 127.4 | 32 | 120 | 70 | 8×M12 | 3/4° | ||||||||||||||||||||

| HPA-G6-600SR | 3110 | 1032 | 802 | 175 | 632 | 470 | 120*200 | 127.4 | 40 | 120 | 70 | 8×M12 | F40 | 1 | |||||||||||||||||||

| HPA-G6-700SR | 3214 | 1062 | 852 | 175 | 736 | 530 | 160*200 | 169.4 | 40 | 120 | 70 | 8×M12 | 1 | ||||||||||||||||||||

| HPA-G6-800SR | 3315 | 1120 | 902 | 175 | 856 | 545 | 160*200 | 169.4 | 45 | 120 | 70 | 8×M12 | 1 | ||||||||||||||||||||

| HPA-G7-800SR | 3345 | 125 | 919 | 210 | 856 | 560 | 200*250 | 210.4 | 45 | 120 | 70 | 8×M12 | F48 | 1 | |||||||||||||||||||

| HPA-G7-900SR | 335 | 1257 | 1003 | 210 | 958 | 570 | 200*250 | 210.4 | 50 | 120 | 70 | 8×M12 | 1 | ||||||||||||||||||||

| HPA-G7-1000SR | 3405 | 1277 | 1057 | 210 | 1068 | 590 | 200*250 | 231.4 | 50 | 120 | 70 | 8×M12 | 1 | ||||||||||||||||||||

| HPA-G8-900SR | 3640 | 1210 | 904 | 265 | 956 | 650 | 220*300 | 231.4 | 50 | 120 | 70 | 8×M12 | F60 | 1-1/4 | |||||||||||||||||||

| HPA-G8-1000SR | 3750 | 1347 | 1058 | 265 | 1068 | 660 | 220*300 | 231.4 | 50 | 120 | 70 | 8×M12 | 1-1/4° | ||||||||||||||||||||

| HPA-G8-1100SR | 3950 | 1367 | 1092 | 265 | 1175 | 710 | 220*300 | 292.4 | 63 | 120 | 70 | 8×M12 | 1-1/4° | ||||||||||||||||||||