Sanitary Tri Clamp 3 Way SS314 Electric Actuated Ball Valve

Sanitary Tri Clamp 3 Way SS314 Electric Actuated Ball Valve

Item Number: HEA Series

The Sanitary Tri-Clamp 3-Way SS314 Electric Actuated Ball Valve offers reliable automation with a maximum torque of 2000 N.m, self-locking worm gear, and corrosion-resistant aluminum alloy housing. Designed for small quarter-turn applications, this IP67-rated valve ensures optimal performance in industries like water treatment, chemical processing, and petroleum with customizable rotation up to 270°.

Description

The Sanitary Tri-Clamp 3-Way SS314 Electric Actuated Ball Valve is designed for precise control of 0° to 270° rotation valves and similar products, including butterfly valves, dampers, and flapper valves. It is widely used across industries such as petroleum, chemical processing, water treatment, shipping, paper manufacturing, and power plants.

Powered by 380V/220V/110VAC or 24V/110VDC, it accepts 4-20mA or 0-10VDC control signals to ensure accurate positioning and fully automated operation. With a maximum torque output of 2000 N.m, it delivers reliable and efficient performance.

Key Product Features

Engineered for small quarter-turn applications, this actuator is built to automate valves with up to 270° rotation. Rated IP67 and compliant with NEMA 4 and 6 standards, it ensures robust protection against harsh environments. An anti-condensation thermal protector safeguards the motor from overheating, enhancing component longevity and reliability.

Performance features

| Function | On/Offor Modulating | ||||||||

| Material | |||||||||

| Housing | Aluminum alloy,epoxy powder coated | ||||||||

| Gear | Steel/aluminum bronze | ||||||||

| Screws | Stainless steel | ||||||||

| Indicator Cover | Polycarbonate | ||||||||

| Shaft/Adaptor | Alloy steel | ||||||||

| Seal | NBR | ||||||||

| Lubrication | Aluminum based grease | ||||||||

| Technical Data | |||||||||

| Power Supply | 24VDC,110VAC,220VAC | ||||||||

| Motor | Squirrelcage asynchronous motor | ||||||||

| Limit Switch | SPDT,250VAC10A,each for Open and Close positions | ||||||||

| Rotation | 90o(±10o)other rotation on request | ||||||||

| Manual Operation | Mechanical handle standard | ||||||||

| Conduit Entry | 2xM18 | ||||||||

| Operating Temp | -20oC to +70oC | ||||||||

| Ambient Humidity | Max.90%RH | ||||||||

| VibrationTested | XYZ10g,0.2~34Hz,30 minutes | ||||||||

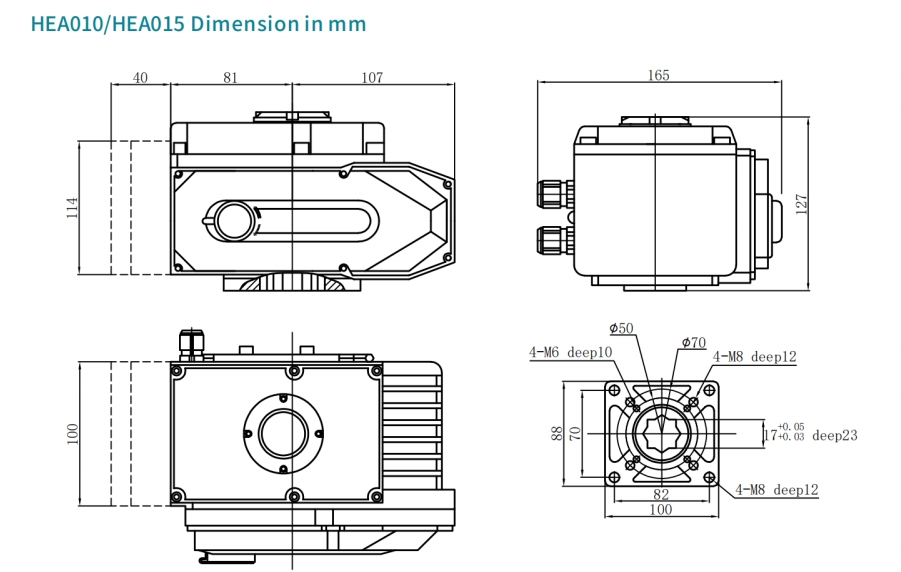

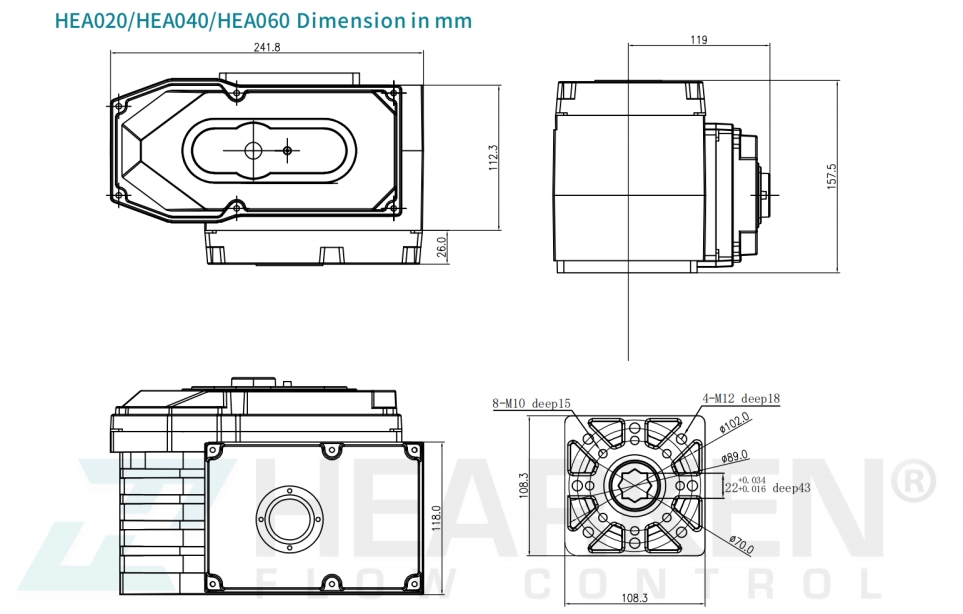

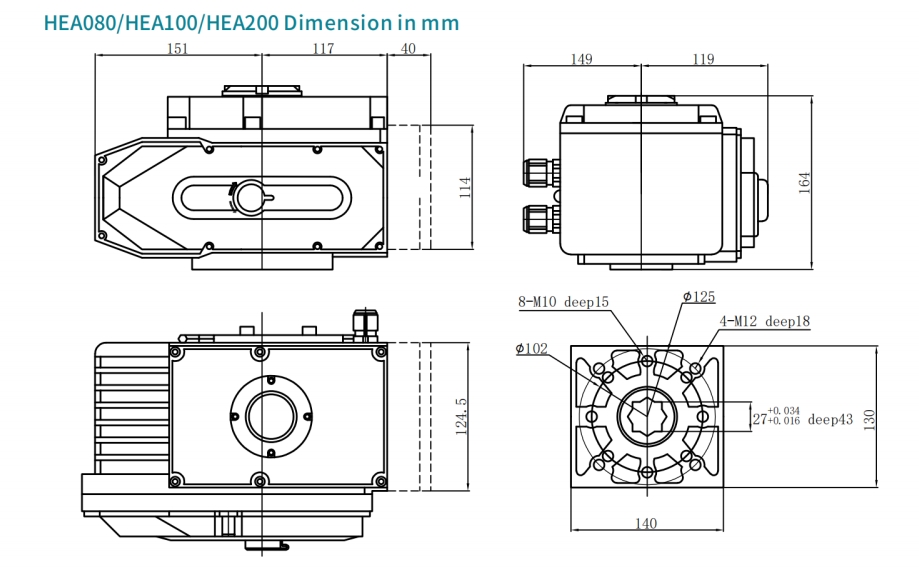

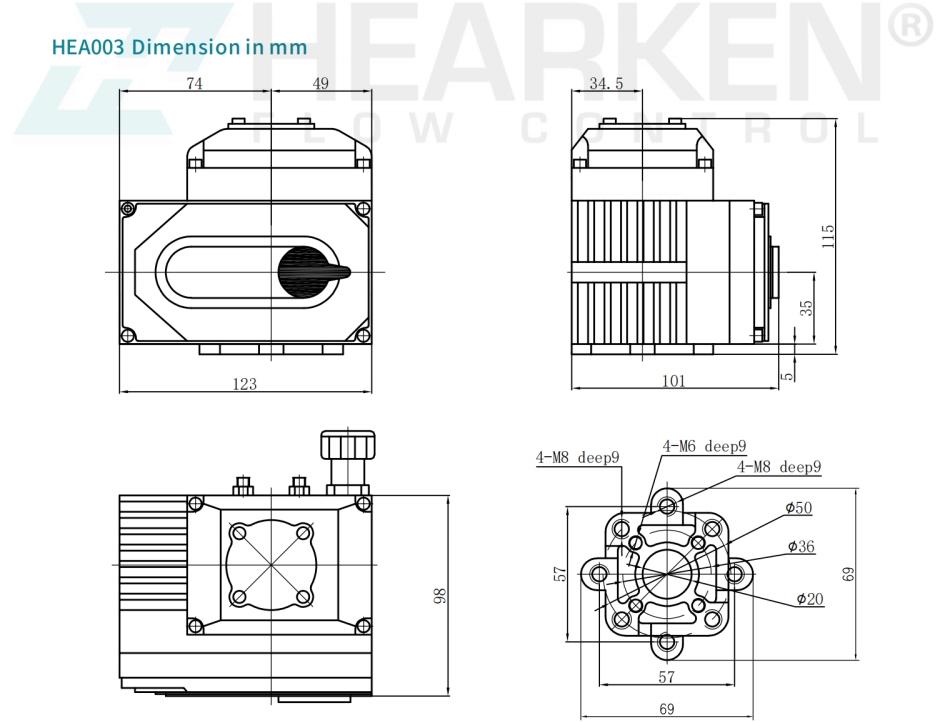

| Mounting | IS05211 | ||||||||

| Torque Output | 30 Nm to 1000 Nm(2000 Nm on request) | ||||||||

| Self-locking device | Self-locking by worm and worm gear | ||||||||

Standard & Technical datas

| Indicator | Dome Type(Option:LED Light Inside) | Enclosure | Waterproof Level IP67,NEMA 4 and6 | ||||||||||||||||||

| Ambient Temp Limit Switches | -20℃~+70℃ | Power Supply Travel Angle | AC110/220V1PH±10%50/60HZ.DC24V | ||||||||||||||||||

| 2 open/close+dry contact 2 open/close | 90°±5°(Extension up to 270°) | ||||||||||||||||||||

| Manual Operation | Hex key(Option: Handwheel) | SelfLocking | Provide self locking by worm gear | ||||||||||||||||||

| Lubrication | Aluminum base grease(EP type) | Conduit entries | 2PF 1/2"(Option: M20x1.5,NPT1/2") | ||||||||||||||||||

| Surface Treatment | Anodizing | External Coating | Dry powder,epoxy polyester | ||||||||||||||||||

Technical Parameter and Specifications(On/Off or Modulating Version)

| Mode | Max Output Torque(N.M) |

Operating Time 90° (Sec.) 220VAC/24VDC |

Drive Shaft(mm) | Motor (W) 220V/24VDC |

Single-phsae rated current(A) 220AC/24vA |

Weight(kg) | Flange Size | ||||||||||||||

| Square | Deep | Round | Deep | ||||||||||||||||||

| HEA003 | 30N.m | 10/10 |

9X9 11X11 |

13.5 15.5 |

Ø12.6 | 26 | 6 | 0.24/1 | 2.1 | F03/F05 | |||||||||||

| HEA005 | 50N.m | 30/13 |

11X11 14X14 |

15.5 18 |

Ø12.6 | 26 | 10 | 0.24/3 | 3.6 | F05/F07 | |||||||||||

| HEA008 | 80N.m | 30/13 |

11X11 14X11 |

15.5 18 |

Ø15.78 | 26 | 12 | 0.25/3.5 | 3.6 | F05/F07 | |||||||||||

| HEA010 | 100N.m | 30/13 |

11X11 14X11 |

18 22.5 |

Ø15.78 Ø18.95 |

28 | 20 | 0.32/4 | 4.6 | F05/F07 | |||||||||||

| HEA015 | 150N.m | 30/13 |

22X22 27X27 |

18 22.5 |

Ø18.95 | 28 | 25 | 0.35/5 | 4.6 | F05/F07 | |||||||||||

| HEA020 | 200N.m | 30/13 | 22X22 | 26 | Ø22.13 | 45 | 40 | 0.5/6 | 8.9 | F07/F10 | |||||||||||

| HEA020 | 200N.m | 30/13 | 22X27 | 32.5 | Ø31.65 | 45 | 40 | 0.5/6 | 14.3 | F10/F12 | |||||||||||

| HEA040 | 400N.m | 30/13 | 22X22 | 26 | Ø22.13 | 45 | 45 | 0.55/9 | 8.9 | F07/F10 | |||||||||||

| HEA040 | 400N.m | 30/13 | 27X27 | 32.5 | Ø31.65 | 45 | 45 | 0.55/9 | 14.3 | F10/F12 | |||||||||||

| HEA060 | 600N.m | 30/13 | 22X22 | 26 | Ø22.13 | 45 | 90 | 0.9/9 | 9.3 | F07/F10 | |||||||||||

| HEA060 | 600N.m | 30/13 | 27X27 | 32.5 | Ø31.65 | 45 | 90 | 0.9/9 | 14.3 | F10/F12 | |||||||||||

| HEA080 | 800N.m | 45/20 | 27X27 | 32.5 | Ø31.65 | 45 | 120 | 1.5/13 | 14.3 | F10/F12 | |||||||||||

| HEA100 | 1000N.m | 45/20 | 27X27 | 32.5 | Ø31.65 | 45 | 120 | 1.5/13 | 14.5 | F10/F12 | |||||||||||

| HEA200 | 2000N.m | 60/23 | 27X27 | 32.5 | Ø31.65 | 45 | 180 | 1.8/15 | 14.5 | F10/F12 | |||||||||||