How to Maintain Pneumatic Valves?

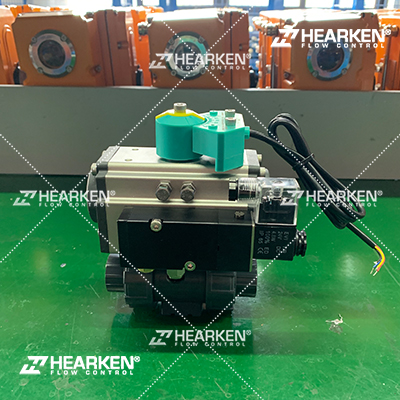

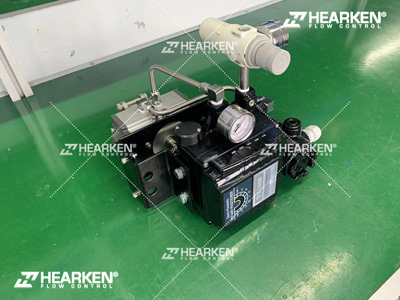

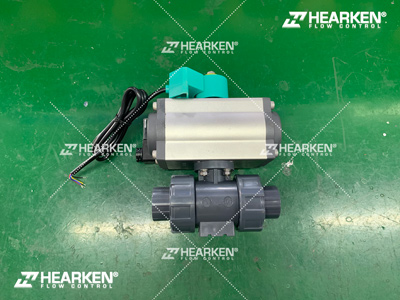

Pneumatic valves are essential components in industrial automation, controlling air and gas flow to ensure efficient operations. Proper maintenance is crucial to extend their lifespan and keep systems running smoothly. Here’s a comprehensive guide on how to maintain pneumatic valves, with key considerations for both storage and in-use maintenance.

Pneumatic Valve Daily Maintenance Tips

1. Storage Conditions

Keep valves in a dry, ventilated area: Pneumatic valves should be stored indoors in a dry, well-ventilated environment to prevent exposure to moisture, which could cause corrosion.

Seal the ends of the valve ports: Ensure that both ends of the valve are securely sealed during storage to protect internal components from dust and debris.

2. Long-Term Storage Checks

Periodic inspections: For valves in long-term storage, conduct regular checks to ensure there are no contaminants or buildup inside the valve.

Apply anti-rust oil: For valves that are not in use for extended periods, apply a layer of anti-rust oil on sealing surfaces to prevent corrosion.

3. Post-Installation Inspections

After installation, regular inspections are critical to ensure that the valve continues to function properly. Key areas to inspect include:

Seal face wear: Check for any wear or damage to the sealing surfaces, which could cause leakage or performance issues.

Stem and stem nut wear: Inspect the stem and its associated threads for signs of wear or damage.

Packing condition: Ensure that the valve packing has not degraded over time. Replace any worn or damaged packing to maintain proper sealing.

Pressure testing: After any major repair or reassembly, always perform a pressure test to check for seal integrity.

Maintenance During Operation

1. Purpose of Regular Maintenance

Regular maintenance helps to extend the life of pneumatic valves and ensures reliable operation.

2. Lubrication of Moving Parts

Lubricate stem threads: The stem threads often experience friction. Apply a small amount of lubricant, such as dry oil, molybdenum disulfide, or graphite powder, to reduce wear.

Lubricate regularly: For valves that do not operate frequently, manually rotate the handwheel to apply lubricant to the stem threads. This prevents the threads from seizing up.

3. Install protective covers

For outdoor valves, install protective covers around the stem to protect it from rain, snow, dust, and rust. This will prevent the valve from becoming clogged or corroded over time.

4. Lubrication of Mechanical Components

If the valve is part of a mechanical system, ensure that the gearbox is regularly lubricated to prevent premature wear and tear.

5. Keep the Valve Clean

Regularly clean the valve to prevent dirt, grime, and debris from accumulating. Contaminants can damage internal parts and affect valve performance.

6. Check for Proper Functionality

Inspect other components: Regularly check the condition of other valve components, such as the handwheel, stem, and actuator. Ensure that parts like the handwheel securing nuts are intact.

Check for leaks: Perform routine leak tests to detect any potential problems with the valve’s sealing surfaces.

7. Avoid Overloading the Valve

Do not use the valve to support heavy objects: Valves should not bear the weight of other heavy components or be used as a support. This can cause mechanical stress and lead to failure over time.

Avoid standing on valves: Never stand on pneumatic valves, as this can damage internal components and compromise their structural integrity.

8. Regular Maintenance of the Stem

The stem, especially the threaded part, should be regularly wiped clean of dirt and debris. Contaminated lubrication can cause increased friction, damaging the threads and reducing valve life. Always replace old lubrication if it becomes dirty or contaminated with abrasive particles.

How to extend the life of pneumatic valves?

Set a Schedule: Inspect, lubricate, and clean valves regularly based on usage and environmental conditions.

Train Staff: Ensure maintenance personnel are trained in proper care and routine inspections.

Use Quality Parts: Opt for recommended lubricants and original spare parts to prevent damage.

Keep Records: Document all maintenance activities to track performance and plan future servicing.

Conclusion

By following these maintenance tips, you can ensure your pneumatic valves operate efficiently and reliably for years to come.