Electric Actuator Ball Valve Flange

Electric Actuator Ball Valve Flange

Item Number: HUM Series

The Electric Actuator Ball Valve with Flange offers precise control, featuring an ISO 5211-compatible design, high torque range, and a reliable mechanical position indicator for real-time monitoring.

Description

The Electric Actuator Ball Valve with Flange is a high-performance solution designed to provide precise control for a wide range of industrial applications.

This electric actuator is built in compliance with ISO5211 standards, ensuring compatibility with various valve types and sizes. The actuator’s torque ranges from 90 kgf-cm² to 35,000 kgf-cm², making it suitable for valves with diverse flow and pressure requirements. We also offer customization services to meet specific application needs.

Each actuator is equipped with a mechanical position indicator, allowing for real-time feedback of the valve’s open or closed position. This feature can be easily integrated with a control box, providing continuous monitoring of the valve’s status. The actuator’s position indicator is highly reliable, offering accurate and clear signals regarding the valve’s operational status.

In addition to its advanced control capabilities, the Electric Actuator Ball Valve is also fitted with a manual override device. This feature allows for manual operation in the event of a power failure, ensuring uninterrupted system control. The override can be easily operated using a wrench or handwheel, providing flexibility and reliability in critical situations.

Designed for a variety of industrial environments, the Electric Actuator Ball Valve with Flange offers durable construction, excellent performance, and ease of integration into existing systems. Its versatile design and reliable functionality make it an ideal choice for applications such as water treatment, chemical processing, and HVAC systems, ensuring efficient and dependable valve control across industries.

Product Characteristics

Enclosure:

The actuator features an IP67-rated enclosure, providing exceptional protection against both dust and water. The standard enclosure is made from high-quality Nylon, offering resistance to heat, acid, and alkali. An aluminum enclosure option is also available for enhanced durability and strength.

Motor:

Designed to be compact yet powerful, the motor offers low energy consumption while delivering high torque. All models are equipped with an F-class insulation system, ensuring optimal performance under a wide range of operating conditions. The motor also includes overheating protection, preventing damage from excessive temperatures and ensuring long-lasting operation.

Position Indicator:

Each actuator comes with a mechanical position indicator mounted on the top of the actuator. This allows for constant monitoring of the valve’s position. The indicator can be connected to a control box, providing real-time feedback of the valve’s open or closed status, ensuring precise control in automated systems.

Special Voltage Options:

In addition to standard voltages, three-phase voltage options such as 220V, 380V, and 440V are available to meet various industrial power requirements.

Manual Override Device:

The actuator is equipped with a manual override feature, which allows for manual operation in the event of a power failure. This can be easily operated using a wrench or handwheel, providing seamless control during emergencies or maintenance.

Flange/Mounting Type (ISO 5211):

The actuator supports direct mounting on ISO 5211-compliant valves (models HUM-1 to HUM-6). For valves that do not conform to ISO 5211 standards, or for applications involving steam or high-temperature fluids, a mounting kit is required to facilitate proper installation.

Working Conditions:

Ambient Temperature: -10°C to 60°C

Humidity: 30% to 95% RH

Product Specification

| Model | Voltage | Current | Rated Power |

Switching Speed (0~90°) |

Output Torque(Nm) |

Max Stroke | Output Connection Size |

Manual Mode |

Provides output adapter sleeve |

| HUMS | AC220V(50Hz) | 30mA | 6W | 25s | 15 | 0~360° | 14x18mm F03/F05 |

N/A | 14X11,14X9 |

| HUMS | AC110V(50Hz) | 35mA | 6W | 25s | 15 | 0~360° | |||

| HUMS | DC24V | 20mA | 6W | 25s | 15 | 0~360° | |||

| HUM-1 | AC220V(50Hz) | 0.25A | 15W | 12s | 35 | 0~360° | 14x18mm F03/F05 |

8mm Square Shaft atthe bottom |

14X11,14X9 |

| HUM-1 | AC220V(50Hz) | 0.25A | 15W | 2.5s | 15 | 0~360° | |||

| HUM-1 | AC220V(50Hz) | 0.25A | 15W | 1s | 7 | 0~360° | |||

| HUM-1 | DC24V | 0.5A | 18W | 10s | 35 | 0~360° | |||

| HUM-1 | DC24V | 0.5A | 18W | 2.5s | 15 | 0~360° | |||

| HUM-1 | DC24V | 0.5A | 18W | 1s | 7 | 0~360° | |||

| HUM-1S | AC220V(50Hz) | 0.25A | 15W | 12s | 50 | 0~360° |

14x18mm F03/F04/F05 |

8mm Square Shaft atthe bottom |

14X11,14X9 |

| HUM-1S | AC220V(50Hz) | 0.25A | 15W | 2.5s | 15 | 0~360° | |||

| HUM-1S | AC220V(50Hz) | 0.25A | 15W | 1s | 7 | 0~360° | |||

| HUM-1S | DC24V | 0.5A | 18W | 10s | 50 | 0~360° | |||

| HUM-1S | DC24V | 0.5A | 18W | 2.5s | 15 | 0~360° | |||

| HUM-1S | DC24V | 0.5A | 18W | 2.5s | 7 | 0~360° | |||

| HUM-2 | AC220V(50Hz) | 0.25A | 15W | 23s | 75 | 0~360° |

14x18mm F04/F05/F07 |

8mm Square Output Shaft atthe | 14X11,14X9 |

| HUM-2 | DC24V | 0.5A | 18W | 20s | 75 | 0~360° | |||

| HUM-3 | AC220V(50Hz) | 0.45A | 25W | 8s | 150 | 0~360° |

17x20mm F07 |

8mm Square Output Shaft atthe | 17x14 |

| HUM-3 | AC220V(50Hz) | 0.45A | 25W | 1s | 35 | 0~360° | |||

| HUM-3 | AC380V(50Hz) | 0.25A | 30W | 8s | 160 | 0~360° | |||

| HUM-3 | AC380V(50Hz) | 0.25A | 30W | 1s | 45 | 0~360° | |||

| HUM-3 | DC24V | 0.3A | 30W | 8s | 150 | 0~360° | |||

| HUM-3 | DC24V | 0.3A | 30W | 1s | 45 | 0~360° | |||

| HUM-3-1 | AC220V(50Hz) | 0.45A | 25W | 8s | 150 | 0~360° |

17x20mm F07 |

Lateral Handwheel | 17x14 |

| HUM-3-1 | AC220V(50Hz) | 0.45A | 25W | 1s | 35 | 0~360° | |||

| HUM-3-1 | AC380V(50Hz) | 0.25A | 30W | 8s | 160 | 0~360° | |||

| HUM-3-1 | AC380V(50Hz) | 0.25A | 30W | 1s | 45 | 0~360° | |||

| HUM-3-1 | DC24V | 0.3A | 30W | 8s | 150 | 0~360° | |||

| HUM-3-1 | DC24V | 0.3A | 30W | 1s | 45 | 0~360° | |||

| HUM-4 | AC220V(50Hz) | 0.45A | 25W | 20s | 250 | 0~360° |

22x30mm F07/F10 |

Lateral Handwheel | 22x17 |

| HUM-4 | AC220V(50Hz) | 0.45A | 25W | 30s | 330 | 0~360° | |||

| HUM-4 | AC380V(50Hz) | 0.25A | 30W | 20s | 250 | 0~360° | |||

| HUM-4 | AC380V(50Hz) | 0.25A | 30W | 30s | 330 | 0~360° | |||

| HUM-4 | DC24V | 0.3A | 30W | 20s | 250 | 0~360° | |||

| HUM-4 | DC24V | 0.3A | 30W | 30s | 330 | 0~360° | |||

| HUM-5 | AC220V(50Hz) | 0.55A | 40W | 30s | 450 | 0~360° |

22x34mm F10/F12 |

Lateral Handwheel | 27x22 |

| HUM-5 | AC380V(50Hz) | 0.25A | 40W | 30s | 450 | 0~360° | |||

| HUM-6 | AC220V(50Hz) | 0.65A | 60W | 30s | 600 | 0~360° |

22x34mm F10/F12 |

Lateral Handwheel | 27x22 |

| HUM-6 | AC380V(50Hz) | 0.65A | 60W | 30s | 600 | 0~360° |

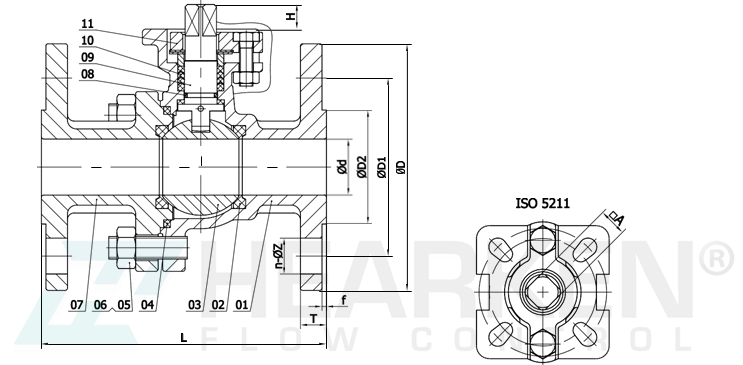

Basic Ball Valve Outline Dimension(Unit:mm)

| No. | Description | Material | ||||

| 11 | Packing Gland | 304 | ||||

| 10 | Stem Packing | PTFE | ||||

| 09 | Stem | 304/316 | ||||

| 08 | O-ring | VITON | ||||

| 07 | Bonnet | CF8/CF8M | ||||

| 06 | Bolt | 304 | ||||

| 05 | Nut | 304 | ||||

| 04 | Body Gasket | PTFE | ||||

| 03 | Ball | 304/316 | ||||

| 02 | Ball Seat | PTFE | ||||

| 01 | Body | CF8/CF8M | ||||

| Model | Rated Torque (N.m) |

Consumption(W) | 0~90° (Sec) |

Dimension (mm) | |||||||||||||||||||||||||||||||

| AC110V AC220V |

DC24V | ||||||||||||||||||||||||||||||||||

| A | B | C | D | E | F | L | M | N | 0 | P | |||||||||||||||||||||||||

| HUM1-N | 6 | 23 | 22 | 3 | 116 | 145 | 19 | - | 140 | 14 | - | - | - | - | 8 | ||||||||||||||||||||

| 16 | 13 | 11 | 8 | ||||||||||||||||||||||||||||||||

| 27 | 14 | ||||||||||||||||||||||||||||||||||

| HUM2-5-N | 35 | 16 | 15 | 15 | |||||||||||||||||||||||||||||||

| HUM2-7-N | 50 | 20 | 19 | 17 | |||||||||||||||||||||||||||||||

| HUM3-N/ HUM3-1-N |

25 | 90 | 80 | 2 | 173 | 244 | 30 | 250 | 203 | 17 | 330 | 85 | 65 | 59 | 123 | ||||||||||||||||||||

| 115 | 65 | 60 | 8 | ||||||||||||||||||||||||||||||||

| HUM4-N | 250 | 45 | 38 | 30 | 173 | 270 | 30 | 250 | 203 | 22 | 330 | 85 | 65 | 85 | 123 | ||||||||||||||||||||

| HUM5-N | 365 | 55 | 48 | 33 | 173 | 276 | 34 | 250 | 203 | 27 | 330 | 85 | 65 | 92 | 123 | ||||||||||||||||||||

| HUM6-N | 456 | 85 | 82 | 26 | |||||||||||||||||||||||||||||||