Modulating Quarter Turn Electric Actuator With Handwheel for Ball Valve

Modulating Quarter Turn Electric Actuator With Handwheel for Ball Valve

Item Number: HEA series

This Modulating Quarter Turn Electric Actuator's mechanical design also includes a manual operation feature and built-in overheating protection, offering both convenience and safety in demanding environments.

Description

The Modulating Quarter Turn Electric Actuator with Handwheel for Ball Valves is an electric-powered device designed to precisely rotate a valve for opening or closing. Controlled by a modulating signal in the range of 4–20mA, this actuator adjusts the valve position in response to changes in flow or pressure. The 4–20mA modulating signal is a widely adopted standard in industrial applications, offering reliable, accurate communication for precise valve control. This ensures optimal regulation of the process, enhancing system performance and stability.

The rotary electric actuator is ideal for various applications, including water treatment, chemical processing, and oil and gas refineries. Its versatility, combined with dependable performance, helps improve system efficiency while reducing the need for frequent maintenance.

Main Product features

Designed for small quarter-turn applications.

Protection class to IP67, NEMA4 and 6

The Actuator can automate the valves requiring up to 270 degree rotation.To help protect the components and extend the actuator's life, an anti-condensation A thermal protector is provided to protect the motor from over heating.

Performance Features

| Fuction: | On/off or modulating |

| Material | |

| Housing: | Aluminum alloy,epoxy powder coated |

| Gear: | Steel/aluminum bronze |

| Screws: | Stainless steel |

| Indicator Cover: | Polycarbonated |

| Shaft/Adaptor: | Alloy steel |

| Seal: | NBR |

| Lubrication: | Aluminum based grease |

| Technical Date | |

| Power Supply: | 24VDC,110VAC,220VAC |

| Motor: | Squirrel cage asynchronous motor |

| Limit Switch | SPDT,250VAC 10A,each for open and close positions |

| Rotation: | 90° (±10°)other rotation on request |

| Manual Operation: | Mechanical handle standard |

| Conduit Entry: | 2 x M18 |

| Operating Temp: | -20°C to + 70°C |

| Ambient Humidity: | Max.90%RH |

| Vibration Tested: | XYZ10g,0.2~34Hz,30 minutes |

| Mounting: | ISO5211 |

| Torque Output: | 30Nm to 1000Nm (2000Nm on request) |

| Self-locking device: | Self-locking by worm and worm gear |

Options Available

| Space Heater, 7 ... 10W (110/220VAC)* |

| Stall Protection, internal overheating protection, open @ 120oC / close @ 97oC (± 5oC)* |

| Position Feedback Potentiometer (1K ... 10K)* |

| Position Feedback Sensor with Current output (4 ... 20mA)* |

| Proportional Control Unit for modulating control (input/output signal, 4 ... 20mA, 1 ... 5 VDC, 1 ... 10VDC)* |

| Field control unit (Local control open/stop/close switch, Local/remote control switch)* |

| Power Failure Self Reset |

Standard & Technical datas

| Indicator | Dome Type( Option: LED Light Inside) | Enclosure | Waterproof Level IP67,NEMA4 and 6 |

| Ambient Temp | -20℃~+70℃ | Power Supply | AC110/220V 1PH±10% 50/60HZ.DC24V |

| Limit Switches | 2 open/close+dry contact 2 open/close | Travel Angle | 90º±5°(Extension up to 270º) |

| Manual Operation | Hex key (Option: Handwheel) | Self Locking | Provide self locking by worm gear |

| Space Heater | 5W(110/230VAC,24VDC) | Conduit entries | 2PF 1/2''(Option:M20x1.5,NPT1/2'') |

| Lubrication | Aluminum base grease(EP type) | External Coating | Dry powder, epoxy polyester |

| Surface Treatment | Anodizing | Material | Aluminum Alloy, Steel, Alloy Bronze |

Testing For All Actuators

All actuators manufactured by HEARKEN are individually tested. Testing is carried out to check the leakage in both internal and external. The angle of rotation and Torque values. All bodies are stamped with year, month of production, size and serial number.

Technical Parameter and Specifications (On/Off or Modulating Version)

|

Model |

Max Output Torque (N.m) |

Operating Time 90°(Sec.) |

Drive Shaft(mm) |

Motor (W) |

Single-phsae rated current(A) 220VAC/24VDC |

Weight (kg) |

Flange Size |

|||

|

Square |

Deep |

Round |

Deep |

|||||||

|

HEA003 |

30N.m |

10/10 |

9X9 |

13.5 |

Ø12.6 |

26 |

8 |

0.15// |

2.5 |

F03/F05 |

|

11X11 |

15.5 |

|||||||||

|

HEA005 |

50N.m |

30/15 |

11X11 |

15.5 |

Ø12.6 |

26 |

10 |

0.25/2.2 |

4.1 |

F05/F07 |

|

14X14 |

18 |

|||||||||

|

HEA008 |

80N.m |

30/15 |

11X11 |

15.5 |

Ø15.78 |

26 |

10 |

0.25/2.2 |

4.1 |

F05/F07 |

|

14X14 |

18 |

|||||||||

|

HEA010 |

100N.m |

30/15 |

14X14 |

18 |

Ø15.78 |

28 |

15 |

0.35/3.5 |

5.1 |

F05/F07 |

|

17X17 |

22.5 |

Ø 18.95 |

||||||||

|

HEA015 |

150N.m |

30/15 |

14X14 |

18 |

Ø18.95 |

28 |

15 |

0.37/3.5 |

5.1 |

F05/F07 |

|

17X17 |

22.5 |

|||||||||

|

HEA020 |

200N.m |

30/15 |

22X22 |

26 |

Ø22.13 |

45 |

45 |

0.3/7.2 |

9.4 |

F07/F10 |

|

HEA040 |

400N.m |

30/15 |

22X22 |

26 |

Ø28.48 |

45 |

60 |

0.33/7.2 |

9.4 |

F07/F10 |

|

HEA060 |

600N.m |

30/15 |

27X27 |

32.5 |

Ø31.65 |

45 |

90 |

0.33/7.2 |

9.8 |

F07/F10 |

|

HEA080 |

800N.m |

40/20 |

27X27 |

32.5 |

Ø31.65 |

45 |

180 |

0.47/11 |

15 |

F10/F12 |

|

HEA100 |

1000N.m |

40/20 |

27X27 |

32.5 |

Ø31.65 |

45 |

180 |

0.47/11 |

15 |

F10/F12 |

|

HEA200 |

2000N.m |

45/22 |

27X27 |

32.5 |

Ø31.65 |

45 |

180 |

1.5/15 |

15.3 |

F10/F12 |

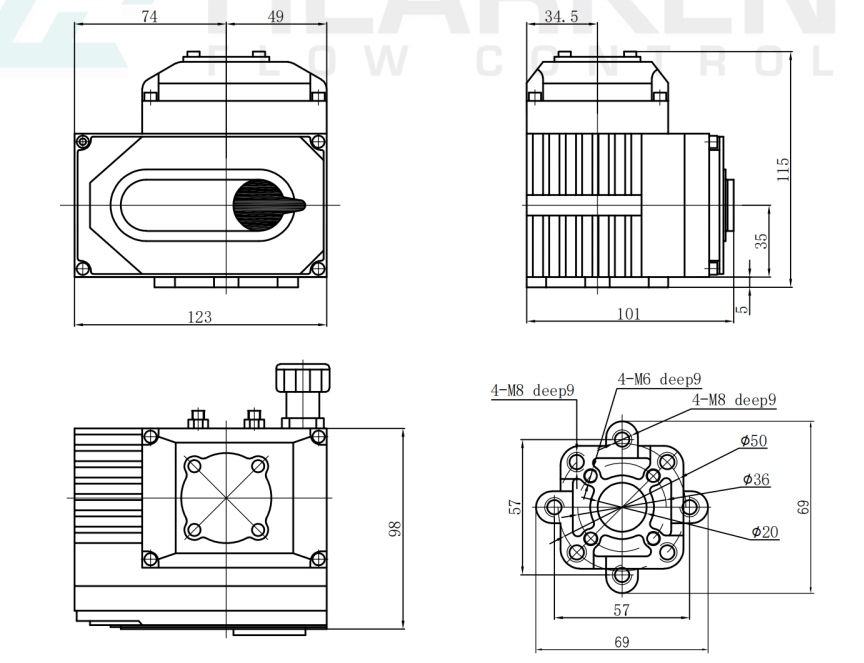

HEA003 Dimensionin mm

HEA005/HEA008 Dimensionin mm

HEA010/HEA015 Dimensionin mm

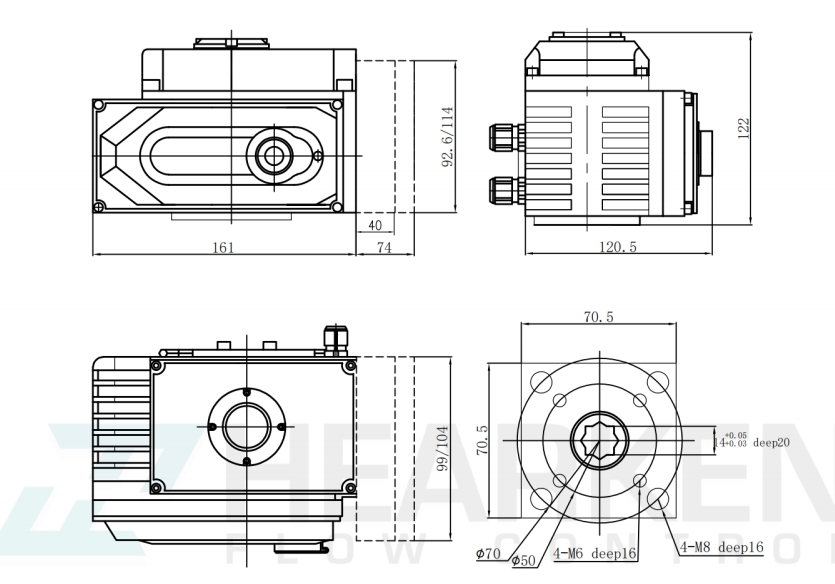

HEA020/HEA040/HEA060 Dimensionin mm

HEA080/HEA100/HEA200 Dimensionin mm