Aluminum Alloy Pneumatic Actuator Quarter Turn

Aluminum Alloy Pneumatic Actuator Quarter Turn

Item Number: HAT series

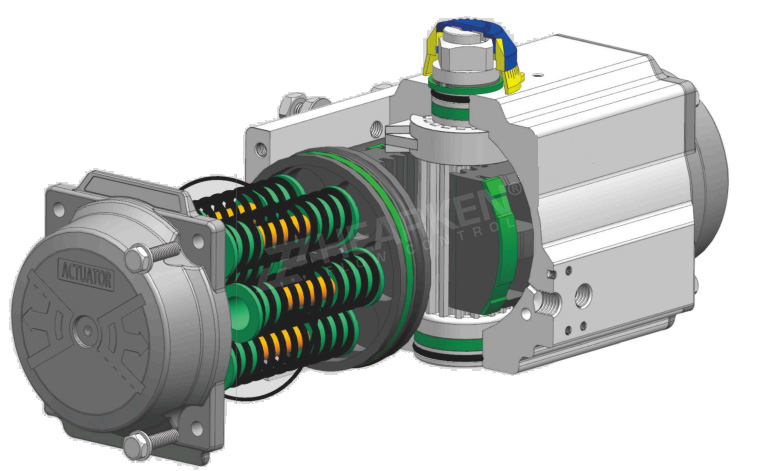

Our fifth generation improved series pneumatic actuators are engineered with advanced materials and precision machining, ensuring a long service life and minimal maintenance requirements with output torque capabilities reaching up to 8000Nm, these actuators are suitable for various applications, including quarter and multi-turn valves.

Description

►Flexible and reliable solutions

Combining high-quality products with rich on-site and design experience, HEARKEN

company meets the expectations of all users and markets by providing flexible, reliable, and

customized solutions, as well as qualified service

►Innovative patent design

The newly developed technological features are integrated into the fifth generation

improved series of pneumatic actuator products, providing more versatility for increasingly

convenient valve automation. The fifth generation improved series pneumatic actuator

products have obtained national patent technology.

►The most complete product range and options

The improved series of pneumatic actuators can provide the following types of products

-16 specifications of products

-Spring reset (single acting) and double acting methods

-The output torque can reach 8000Nm

-Multiple different surface anti-corrosion grades

-High temperature and low temperature structures

-Multiple ISO standard connecting flanges and drive shafts facilitate direct connection with valves

-Spring reset (single acting) and double acting both have a rotation angle of 120-135-180 degrees

-180 spring reset (single acting) actuator with FAIL-MIN function

-The three position actuator, with a rotation stroke of 90 and 180, can be achieved in both spring reset (single acting) and double acting modes.

-Quick action execution mechanism

►High quality grade products

The fifth generation improved series pneumatic actuator products have undergone a completely new design and testing, achieving the longest

service life and most reliable performance through minimal maintenance and upkeep.

►Complies with international standards

The design, production, and testing of the fifth generation improved series pneumatic actuator products fully comply with all applicable

international standards.

►Production process and materials

The fifth generation improved series pneumatic actuator products are produced using high-quality materials, the most precise material

selection, and the latest production processes.

Technical Features

1. Anode hardened cylinder body

The extruded aluminum alloy cylinder body undergoes special anodic hardening treatment on the inner and outer surfaces to achieve

comprehensive anti-corrosion protection, with low friction coefficient and increased surface hardness to make it more wear-resistant.

In order to meet different environmental conditions, various anti-corrosion coatings can be provided on its outer surface.

2. Piston structure

The dual piston toothed strip structure makes it compact, symmetrically installed, has a long service life, and can move quickly. On site,

simply flipping the piston can achieve reverse rotation, and the anode hardening of the

piston makes it more corrosion-resistant and wear-resistant.

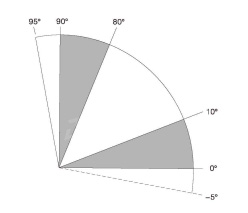

3. Two independent external travel limit adjustments

As a standard actuator, the adjustable range of travel limit in the closed position is -5 ° to

10 °, and in the open position it is 5 ° to -10 °. This allows for precise adjustment of valve

stroke, setting of stroke, and providing a larger range of stroke adjustment.

4. A drive shaft with strong universality and anti fracture structure

The conversion between parallel and diagonal regular quadrilaterals is convenient, and it can also provide a dual regular quadrilateral

structure (diagonal and parallel) drive shaft, which facilitates more flexible and lower inventory.

5. Top adapter of drive shaft

At relatively high temperatures, the top aluminum alloy adapter connected to the accessory is more precise and stable when matched

with the accessory drive shaft. It is suitable and available for both single square (diagonal or parallel) and double square drive shafts.

6. A compact and stylish structure

The dual acting and spring reset (single acting) actuators have the same cylinder body and end cap, which reduces inventory. By adding

and removing the spring yellow component module, the mode of action can be changed on site.

7. Position indication

The new top adapter is combined with the new valve position indicator. Simply rotate the top adapter and position indicator 90 degrees

to easily adjust the position indication of the actuator valve. This operation can also be conveniently completed on site without the

need to disassemble the actuator.

8. Composite bearings and guide rings

The composite bearings on the piston and rack can achieve precise operation, low friction, and long service life. The piston guide ring

can prevent the output shaft from breaking.

9. Combination preload spring

The spring seat of advanced coated steel structure has the characteristics of single and strong universality, which is safer and more

corrosion-resistant.

10. Nickel plated drive shaft

The anti fracture structure and bearing guidance can improve safety and maximize the service life of the drive shaft.

11. Precision machining of teeth

The piston rack and drive shaft gear can achieve precise positioning, with small backlash and maximum meshing to achieve efficient

operation throughout the entire process.

12. Select high-quality bearings and seals

Wide operating temperature range, low friction, long lifespan.

13. Bolt fasteners

Stainless steel bolt fasteners can resist corrosion for a long time.

14. Fully comply with various international standards

The products provided fully comply with international standards such as IS05211, DIN3337, and VDIVDE3845, which enables better interchangeability and easier installation of valves and various accessories.

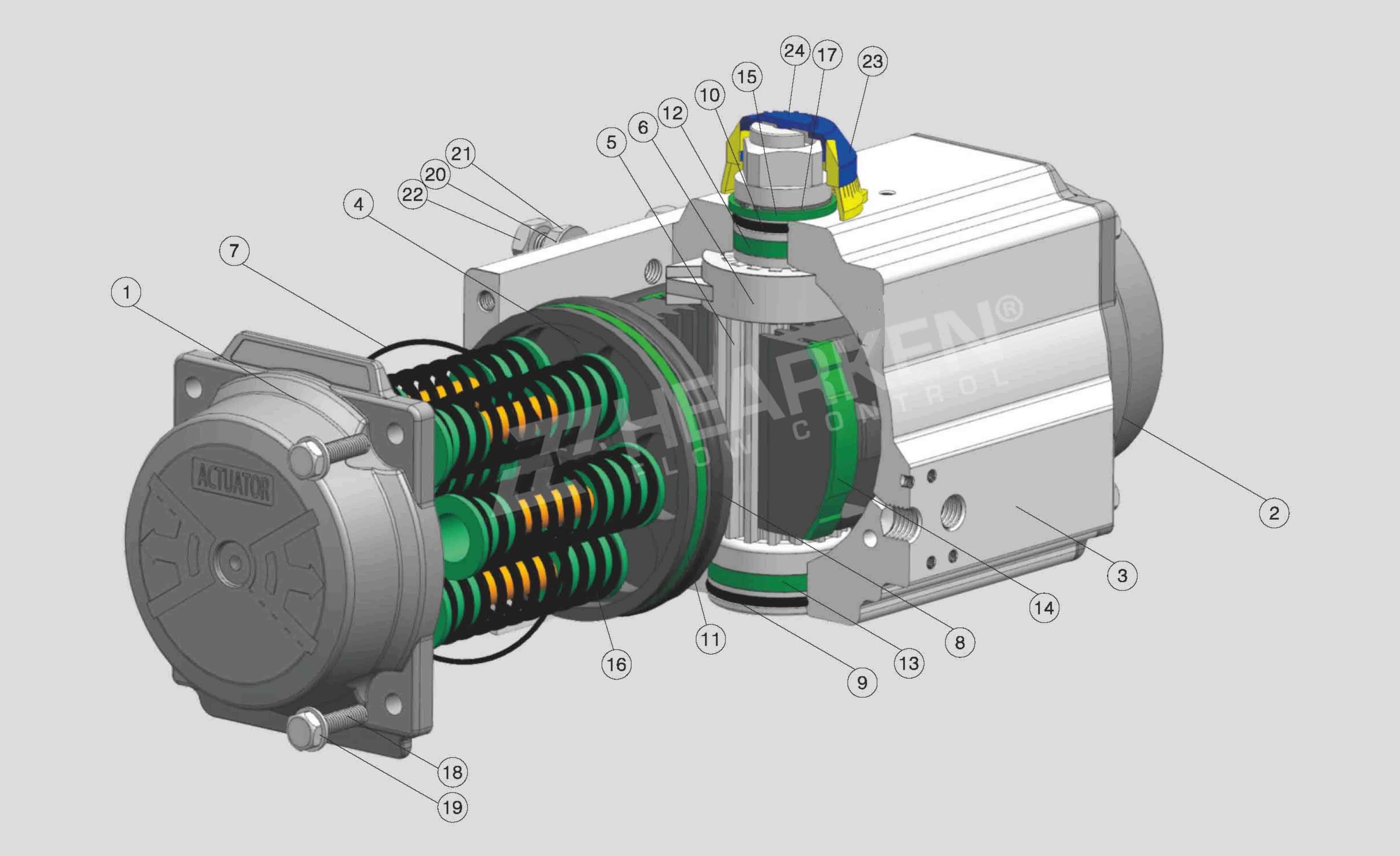

| Part NO. | Quantity | Part name | Material | |||||||||||||||||||||||||||||||||||||||

| 1 | 1(1) | Left End Cover | Die Cast Aluminum Alloy | |||||||||||||||||||||||||||||||||||||||

| 2 | 1(1) | Right End Cover | Die Cast Aluminum Alloy | |||||||||||||||||||||||||||||||||||||||

| 3 | 1 | Cylinder Body | Extruded Aluminum Alloy | |||||||||||||||||||||||||||||||||||||||

| 4 | 2 | Piston | Die Cast Aluminum Alloy | |||||||||||||||||||||||||||||||||||||||

| 5 | 1 | Output Shaft | Carbon Steel | |||||||||||||||||||||||||||||||||||||||

| 6 | 1 | Adjust Cam | Stainless Steel | |||||||||||||||||||||||||||||||||||||||

| 7* | 2 | O-ring (End Cover) | Nitrile Rubber | |||||||||||||||||||||||||||||||||||||||

| 8* | 2 | O-ring (Piston) | Nitrile Rubber | |||||||||||||||||||||||||||||||||||||||

| 9* | 1 | O-ring (Bottom of Output Shaft) | Nitrile Rubber | |||||||||||||||||||||||||||||||||||||||

| 10* | 1 | O-ring (Top of Output Shaft) | Nitrile Rubber | |||||||||||||||||||||||||||||||||||||||

| 11* | 2 | Bearing (Piston) | Fluorocarbon Composite Material | |||||||||||||||||||||||||||||||||||||||

| 12* | 1 | Bearing (top of output shaft) | Nylon 46 | |||||||||||||||||||||||||||||||||||||||

| 13* | 1 | Bearing (Bottom of Output Shaft) | Nylon 46 | |||||||||||||||||||||||||||||||||||||||

| 14* | 1 | Guide Bearing (Back of Piston) | Nylon 46 | |||||||||||||||||||||||||||||||||||||||

| 15* | 2 | Thrust Bearing (Output Shaft) | Nylon 46 | |||||||||||||||||||||||||||||||||||||||

| 16 | 5-12 | Spring Components | Alloy Spring Steel | |||||||||||||||||||||||||||||||||||||||

| 17 | 1 | Elastic Retaining Ring | Stainless Steel | |||||||||||||||||||||||||||||||||||||||

| 18 | 8 | End Cap Bolt | Stainless Steel | |||||||||||||||||||||||||||||||||||||||

| 19 | 8 | End Cap Gasket | Stainless Steel | |||||||||||||||||||||||||||||||||||||||

| 20 | 2 | Gasket | Stainless Steel | |||||||||||||||||||||||||||||||||||||||

| 21 | 2 | Nut Cap | Stainless Steel | |||||||||||||||||||||||||||||||||||||||

| 22 | 2 | Adjust Bolt | Stainless Steel | |||||||||||||||||||||||||||||||||||||||

| 23 | 1 | Indicator | Nylon PA66 | |||||||||||||||||||||||||||||||||||||||

| 24 | 1 | Screw | Nylon PA66 | |||||||||||||||||||||||||||||||||||||||

Single Acting Output Torque

| Gas Source Pressure | 2.5bar | 3bar 0°90° |

4bar 0° 90° |

5bar 0° 90° |

6bar 0° 90° |

7bar 0° 90 |

8bar 0° 90° |

Spring 0° |

Stroke 90° |

||||||||||||||||||||||||||||||||||||

| Actuator | Spring Group | 0° 90° | |||||||||||||||||||||||||||||||||||||||||||

| Start/End | Start/End | Start/End | Start/End | Start/End | Start/End | Start/End | Start | End | |||||||||||||||||||||||||||||||||||||

| S1 | 5.0/3.0 | 7/4.7 | 10.0/8 | 13.3/11.3 | 53 | 33 | |||||||||||||||||||||||||||||||||||||||

| S2 | 4/1.9 | 6.0/3.6 | 9.3/6.9 | 12.7/10.2 | 64 | 40 | |||||||||||||||||||||||||||||||||||||||

| S3 | 5.3/2.5 | 8.7/5.8 | 12.0/9.2 | 15.3/12.5 | 74 | 46 | |||||||||||||||||||||||||||||||||||||||

| HPA050SR | S4 S5 |

8.0/5 7.3/3.7 |

11.3/8.1 10.7/7.0 |

14.7/11.4 14.0/10 |

18.0/14.7 17.3/13.7 |

20.6/17.0 | 85 96 |

53 5.9 |

|||||||||||||||||||||||||||||||||||||

| S6 | 10.0/6.0 | 13.3/9.3 | 16.7/12.6 | 20.0/16 | 106 | 66 | |||||||||||||||||||||||||||||||||||||||

| S7 | 9.4/4.9 | 13/8.2 | 16.0/11.6 | 19.3/14.9 | 117 | 73 | |||||||||||||||||||||||||||||||||||||||

| S8 | 12.0/7.2 | 15.3/10.5 | 18.7/13.8 | 128 | 79 | ||||||||||||||||||||||||||||||||||||||||

| HPA063SR | S 05 | 9.1/6.2 | 12/9.2 | 17.9/15 | 23.8/20.9 | 84 | 55 | ||||||||||||||||||||||||||||||||||||||

| S 06 | 8/4.5 | 10.9/7.5 | 16.8/13.3 | 22.7/19.2 | 101 | 67 | |||||||||||||||||||||||||||||||||||||||

| S 07 | 9.8/5.8 | 15.7/11.6 | 21.5/17.5 | 27.4/23.4 | 118 | 78 | |||||||||||||||||||||||||||||||||||||||

| S 08 | 14.6/10 | 20.4/15.8 | 26.3/21.7 | 32.227.5 | 135 | 89 | |||||||||||||||||||||||||||||||||||||||

| S 09 | 13.5/8.3 | 19.3/14.1 | 25.2/20 | 311,259 | 36.9/31.7 | 152 | 10 | ||||||||||||||||||||||||||||||||||||||

| S 10 | 18.2/12.4 | 24.1/18.3 | 299,242 | 35.8/30 | 169 | 111 | |||||||||||||||||||||||||||||||||||||||

| S11 | 17.1/10.8 | 23/16.6 | 288,225 | 34.7/28.3 | 186 | 122 | |||||||||||||||||||||||||||||||||||||||

| S 12 | 21.9/14.9 | 277,208 | 33.6/26.7 | 202 | 133 | ||||||||||||||||||||||||||||||||||||||||

| S 05 | 18/11.8 | 23.8/17.6 | 35.5/29.2 | 47.1/40.9 | 173 | 11 | |||||||||||||||||||||||||||||||||||||||

| S 06 | 15.8/8.3 | 21.6/14.1 | 33.3/25.8 | 44.9/37.4 | 21 | 133 | |||||||||||||||||||||||||||||||||||||||

| S07 | 19.4/10.7 | 31.1/22.3 | 42.7/33.9 | 54.3/45.6 | 242 | 155 | |||||||||||||||||||||||||||||||||||||||

| HPA075SR | S 08 S 09 |

28.8/18.8 26.6/15.4 |

40.5/30.5 38.3/27 |

52.1/42.1 49.9/38.6 |

63.7/53.7 61.5/50.3 |

73.2/61.9 | 277 31 |

177 199 |

|||||||||||||||||||||||||||||||||||||

| S10 | 36.1/23.6 | 47.7/35.2 | 59.3/46.8 | 71/58.5 | 346 | 221 | |||||||||||||||||||||||||||||||||||||||

| S11 | 33.8/20.1 | 45.5/31.7 | 57.1/43.4 | 68.7/55 | 381 | 243 | |||||||||||||||||||||||||||||||||||||||

| S 12 | 43.3/28.3 | 54.9/39.9 | 66.5/51.5 | 415 | 265 | ||||||||||||||||||||||||||||||||||||||||

| HPA088SR | S 05 | 27.4/16.9 | 36.6/26 | 54.9/44.3 | 73.2/62.6 | 289 | 183 | ||||||||||||||||||||||||||||||||||||||

| S 06 | 23.8/11.1 | 32.9/20.3 | 51.2/38.6 | 69.5/56.9 | 347 | 22 | |||||||||||||||||||||||||||||||||||||||

| S 07 | 29.2/14.5 | 47.5/32.8 | 65.8/51.1 | 84.2/69.4 | 404 | 257 | |||||||||||||||||||||||||||||||||||||||

| S 08 | 43.9/27 | 62.2/45.3 | 80.5/63.6 | 98.8/81.9 | 462 | 293 | |||||||||||||||||||||||||||||||||||||||

| S09 | 40.2/21.2 | 58.5/39.5 | 76.8/57.8 | 95.1/76.1 | 113/94.5 | 52 | 33 | ||||||||||||||||||||||||||||||||||||||

| S 10 | 54.8/33.8 | 73.1/52.1 | 91.5/70.4 | 110/88.7 | 578 | 367 | |||||||||||||||||||||||||||||||||||||||

| S11 | 51.2/28 | 69.5/46.3 | 87.8/64.6 | 106/82.9 | 635 | 403 | |||||||||||||||||||||||||||||||||||||||

| S 12 | 65.8/40.5 | 84.1/58.8 | 102/77.1 | 693 | 44 | ||||||||||||||||||||||||||||||||||||||||

| S 05 | 41.1/27.1 | 54.4/40.4 | 81/67 | 108/93.6 | 394 | 253 | |||||||||||||||||||||||||||||||||||||||

| S 06 | 36.1/19.2 | 49.4/32.5 | 76/59.1 | 103/85.7 | 473 | 304 | |||||||||||||||||||||||||||||||||||||||

| S07 | 44.3/24.6 | 70.9/51.2 | 97/77.8 | 124/104 | 551 | 355 | |||||||||||||||||||||||||||||||||||||||

| HPA100SR | S 08 S 09 |

65.8/43.3 60.8/35.5 |

92.4/69.9 87.3/62.1 |

119.0/96.5 113.9/886 |

146/123 141/115 |

167/142 | 63 709 |

405 456 |

|||||||||||||||||||||||||||||||||||||

| S 10 | 82.3/54.2 | 109/80.8 | 135/107 | 162/134 | 788 | 507 | |||||||||||||||||||||||||||||||||||||||

| S 11 | 77.2/46.3 | 104/72.9 | 130/99 | 157/126 | 867 | 557 | |||||||||||||||||||||||||||||||||||||||

| S 12 | 99/65 | 125/92 | 152/118 | 945 | 608 | ||||||||||||||||||||||||||||||||||||||||

| HPA115SR | S 05 | 66.5/41.9 | 87.9/63.4 | 131/106 | 174/149 | 655 | 41 | ||||||||||||||||||||||||||||||||||||||

| S 06 | 58.3/28.8 | 79.7/50.3 | 123/93.3 | 166/136 | 786 | 492 | |||||||||||||||||||||||||||||||||||||||

| S 07 | 71.5/37.2 | 115/80.2 | 158/123 | 200/166 | 917 | 574 | |||||||||||||||||||||||||||||||||||||||

| S 08 | 106.67/1 | 149/110 | 192/153 | 235/196 | 105 | 656 | |||||||||||||||||||||||||||||||||||||||

| S 09 | 98.1/54 | 141/97 | 184/140 | 227/183 | 270/226 | 118 | 738 | ||||||||||||||||||||||||||||||||||||||

| S 10 | 133/83.9 | 176/127 | 219/170 | 262/213 | 131 | 82 | |||||||||||||||||||||||||||||||||||||||

| S | 125/70.8 | 168/114 | 211/157 | 254/200 | 144 | 902 | |||||||||||||||||||||||||||||||||||||||

| S 12 | 159/101 | 202/144 | 245/187 | 157 | 984 | ||||||||||||||||||||||||||||||||||||||||

| S 05 | 86/56.1 | 114/83.8 | 169/139 | 224/195 | 824 | 525 | |||||||||||||||||||||||||||||||||||||||

| S 06 | 75.5/39.6 | 103/67.3 | 159/123 | 214/178 | 989 | 63 | |||||||||||||||||||||||||||||||||||||||

| S 07 | 92.7/50.8 | 148/106 | 203/162 | 259/217 | 115 | 735 | |||||||||||||||||||||||||||||||||||||||

| HPA125SR | S 08 S09 |

138/89.7 127/73.3 |

193/145 182/129 |

248/201 238/184 |

304/256 293/239 |

349/295 | 132 148 |

84 945 |

|||||||||||||||||||||||||||||||||||||

| S 10 | 172/112 | 227/168 | 283/223 | 338/278 | 165 | 105 | |||||||||||||||||||||||||||||||||||||||

| S 11 | 161/95.7 | 217/151 | 272/206 | 328/262 | 181 | 116 | |||||||||||||||||||||||||||||||||||||||

| S12 | 206/135 | 262/190 | 317/245 | 198 | 126 | ||||||||||||||||||||||||||||||||||||||||

| HPA145SR | S 05 | 135/89 | 179/132 | 265/219 | 352/306 | 129 | 824 | ||||||||||||||||||||||||||||||||||||||

| S 06 | 119/63 | 162/106 | 249/193 | 336/280 | 155 | 99 | |||||||||||||||||||||||||||||||||||||||

| S 07 | 146/80 | 233/167 | 320/254 | 406/341 | 180 | 115 | |||||||||||||||||||||||||||||||||||||||

| S08 | 216/142 | 303/229 | 390/316 | 477/403 | 206 | 132 | |||||||||||||||||||||||||||||||||||||||

| S 09 | 200/116 | 287/203 | 374/290 | 460/377 | 547/464 | 232 | 148 | ||||||||||||||||||||||||||||||||||||||

| S 10 | 270/177 | 357/264 | 444/351 | 531/438 | 258 | 165 | |||||||||||||||||||||||||||||||||||||||

| S 11 | 254/151 | 341/238 | 428/325 | 515/412 | 283 | 181 | |||||||||||||||||||||||||||||||||||||||

| S 12 | 324/213 | 411/299 | 498/386 | 309 | 198 | ||||||||||||||||||||||||||||||||||||||||

| S 05 | 171/118 | 228/174 | 342/288 | 455/401 | 166 | 112 | |||||||||||||||||||||||||||||||||||||||

| S 06 | 149/84 | 206/141 | 319/255 | 433/368 | 199 | 135 | |||||||||||||||||||||||||||||||||||||||

| S 07 | 183/108 | 297/221 | 410/335 | 524/448 | 233 | 157 | |||||||||||||||||||||||||||||||||||||||

| HPA160SR | S 08 S 09 |

274/188 252/155 |

388/302 365/268 |

501/415 479/382 |

615/528 592/495 |

706/609 | 266 299 |

180 202 |

|||||||||||||||||||||||||||||||||||||

| S 10 | 343/235 | 456/349 | 570/462 | 683/575 | 332 | 224 | |||||||||||||||||||||||||||||||||||||||

| S 11 | 320/202 | 434/315 | 547/429 | 661/542 | 365 | 247 | |||||||||||||||||||||||||||||||||||||||

| S12 | 411/282 | 525/396 | 638/509 | 399 | 269 | ||||||||||||||||||||||||||||||||||||||||

| HPA190SR | S5 | 332/222 | 438/329 | 651/542 | 824/693 | 309 | 200 | ||||||||||||||||||||||||||||||||||||||

| S6 | 292/161 | 398/267 | 611/480 | 784/631 | 371 | 240 | |||||||||||||||||||||||||||||||||||||||

| S 7 | 252/99 | 358/205 | 571/418 | 744/569 | 433 | 280 | |||||||||||||||||||||||||||||||||||||||

| S8 | 318/143 | 531/356 | 704/507 | 957/782 | 1169/995 | 495 | 320 | ||||||||||||||||||||||||||||||||||||||

| S9 | 491/295 | 664/446 | 917/720 | 1130/933 | 577 | 360 | |||||||||||||||||||||||||||||||||||||||

| S 10 | 451/233 | 624/384 | 877/658 | 1090/871 | 1302/1084 | 618 | 400 | ||||||||||||||||||||||||||||||||||||||

| S 11 | 584/322 | 837/597 | 1050/809 | 1263/1022 | 680 | 440 | |||||||||||||||||||||||||||||||||||||||

| S 12 | 797/535 | 1010/748 | 1223/960 | 742 | 480 | ||||||||||||||||||||||||||||||||||||||||

| Pressure | Output Torque Unit:Nm | Spring Output Torque 90° 0° | ||||||||||||||||||||||||||||||||||||||||||||

| 2.5bar 0° 90° | 3bar 0° 90° |

4bar 0° 90° |

5bar 0° 90° |

6bar 0° 90° |

7bar 0° 90° |

8bar 0° 90° |

||||||||||||||||||||||||||||||||||||||||

| Type | Spring Number | |||||||||||||||||||||||||||||||||||||||||||||

| Start/End | Start/End | Start/End | Start/End | Start/End | Start/End | Start/End | Start/End | |||||||||||||||||||||||||||||||||||||||

| HPA210SR | S5 | 390/285 | 523/418 | 789/684 | 380 | 275 | ||||||||||||||||||||||||||||||||||||||||

| S6 | 335/209 | 468/342 | 734/608 | 1000/874 | 456 | 300 | ||||||||||||||||||||||||||||||||||||||||

| S 7 | 280/133 | 413/266 | 679/532 | 945/798 | 532 | 385 | ||||||||||||||||||||||||||||||||||||||||

| S8 | 358/190 | 624/456 | 890/722 | 1156/988 | 1422/1254 | 608 | 440 | |||||||||||||||||||||||||||||||||||||||

| S9 | 569/380 | 835/646 | 1101/912 | 1367/1178 | 684 | 495 | ||||||||||||||||||||||||||||||||||||||||

| S 10 | 514/304 | 780/570 | 1046/836 | 1312/1102 | 1578/1368 | 760 | 550 | |||||||||||||||||||||||||||||||||||||||

| S 11 | 725/494 | 991/760 | 1257/1026 | 1523/1292 | 836 | 605 | ||||||||||||||||||||||||||||||||||||||||

| S 12 | 670/418 | 936/684 | 1202/950 | 1468/1216 | 912 | 660 | ||||||||||||||||||||||||||||||||||||||||

| HPA240SR | S5 | 552/409 | 744/600 | 1129/985 | 554 | 410 | ||||||||||||||||||||||||||||||||||||||||

| S6 | 470/297 | 662/489 | 1047/874 | 1432/1259 | 665 | 492 | ||||||||||||||||||||||||||||||||||||||||

| S7 | 388/187 | 580/379 | 964/764 | 1349/1149 | 775 | 575 | ||||||||||||||||||||||||||||||||||||||||

| S8 | 498/268 | 883/653 | 1267/1037 | 1652/1422 | 2037/1807 | 886 | 656 | |||||||||||||||||||||||||||||||||||||||

| S9 | 800/542 | 1185/926 | 1569/1311 | 1954/1696 | 998 | 739 | ||||||||||||||||||||||||||||||||||||||||

| S 10 | 718/431 | 1103/816 | 1488/1201 | 1872/1586 | 2257/1970 | 1108 | 821 | |||||||||||||||||||||||||||||||||||||||

| S11 | 1021/705 | 1406/1090 | 1791/1474 | 2176/1859 | 1219 | 903 | ||||||||||||||||||||||||||||||||||||||||

| S 12 | 939/594 | 1323/979 | 1708/1363 | 2093/1748 | 1330 | 985 | ||||||||||||||||||||||||||||||||||||||||

| HPA270SR | S5 | 903/675 | 1195/968 | 1779/1552 | 787 | 560 | ||||||||||||||||||||||||||||||||||||||||

| S6 | 790/519 | 1083/811 | 1667/1396 | 2252/1981 | 943 | 672 | ||||||||||||||||||||||||||||||||||||||||

| S7 | 679/361 | 972/654 | 1556/1238 | 2141/1823 | 1101 | 783 | ||||||||||||||||||||||||||||||||||||||||

| S8 | 860/497 | 1444/1081 | 2029/1666 | 2614/2252 | 3199/2836 | 1258 | 895 | |||||||||||||||||||||||||||||||||||||||

| S9 | 1332/923 | 1917/1509 | 2502/2094 | 3087/2678 | 1416 | 1007 | ||||||||||||||||||||||||||||||||||||||||

| S 10 | 1220/767 | 1805/1352 | 2390/1937 | 2974/2521 | 3560/3107 | 1572 | 1119 | |||||||||||||||||||||||||||||||||||||||

| S11 | 1693/1194 | 2278/1779 | 2862/2364 | 3448/2949 | 1730 | 1231 | ||||||||||||||||||||||||||||||||||||||||

| S 12 | 1582/1037 | 2167/1623 | 2751/2207 | 3336/2792 | 1887 | 1342 | ||||||||||||||||||||||||||||||||||||||||

| HPA300SR | S5 | 1097/729 | 1061 | 730 | ||||||||||||||||||||||||||||||||||||||||||

| S6 | 935/494 | 1316/875 | 1273 | 876 | ||||||||||||||||||||||||||||||||||||||||||

| S7 | 772/258 | 1153/639 | 1916/1402 | 1485 | 1022 | |||||||||||||||||||||||||||||||||||||||||

| S8 | 991/403 | 1754/1166 | 2517/1929 | 1697 | 1168 | |||||||||||||||||||||||||||||||||||||||||

| S9 | 1592/930 | 2355/1693 | 3118/2456 | 1909 | 1314 | |||||||||||||||||||||||||||||||||||||||||

| S 10 | 1430/695 | 2193/1458 | 2956/2221 | 3719/2984 | 4482/3747 | 2122 | 1460 | |||||||||||||||||||||||||||||||||||||||

| S 11 | 2030/1222 | 2793/1985 | 3556/2748 | 4319/3511 | 2334 | 1606 | ||||||||||||||||||||||||||||||||||||||||

| S 12 | 1868/986 | 2631/1749 | 3394/2512 | 4157/3275 | 2546 | 1752 | ||||||||||||||||||||||||||||||||||||||||

| HPA350SR | S5 | 1553/964 | 1702 | 1173 | ||||||||||||||||||||||||||||||||||||||||||

| S6 | 1292/586 | 1863/1157 | 2043 | 1408 | ||||||||||||||||||||||||||||||||||||||||||

| S7 | 1031/208 | 1602/779 | 2745/1922 | 2383 | 1642 | |||||||||||||||||||||||||||||||||||||||||

| S8 | 1341/401 | 2484/1544 | 3626/2686 | 2724 | 1877 | |||||||||||||||||||||||||||||||||||||||||

| S9 | 2224/1165 | 3336/2307 | 4508/3449 | 3064 | 2112 | |||||||||||||||||||||||||||||||||||||||||

| S 10 | 1963/787 | 3105/1929 | 4247/3071 | 5390/4214 | 6532/5356 | 3405 | 2346 | |||||||||||||||||||||||||||||||||||||||

| S11 | 2844/1551 | 3986/2693 | 5129/3836 | 6271/4978 | 3745 | 2581 | ||||||||||||||||||||||||||||||||||||||||

| S 12 | 2584/1172 | 3726/2314 | 4869/3457 | 6011/4599 | 4086 | 2816 | ||||||||||||||||||||||||||||||||||||||||

| HPA400SR | S 7 | 2028/869 | 2880 | 1837 | ||||||||||||||||||||||||||||||||||||||||||

| S8 | 1736/411 | 2550/1225 | 3292 | 2100 | ||||||||||||||||||||||||||||||||||||||||||

| S9 | 2259/768 | 3887/2396 | 3703 | 2362 | ||||||||||||||||||||||||||||||||||||||||||

| S 10 | 1967/311 | 3595/1939 | 5223/3567 | 4115 | 2624 | |||||||||||||||||||||||||||||||||||||||||

| S11 | 3303/1482 | 4931/3110 | 6559/4738 | 4526 | 2887 | |||||||||||||||||||||||||||||||||||||||||

| S 12 | 3012/1025 | 4640/2653 | 6268/4281 | 7895/5908 | 9523/7536 | 4938 | 3149 | |||||||||||||||||||||||||||||||||||||||

| S 13 | 4348/2195 | 5976/3823 | 7603/5450 | 9231/7078 | 5349 | 3412 | ||||||||||||||||||||||||||||||||||||||||

| S 14 | 4057/1738 | 5685/3366 | 7312/4993 | 8940/6621 | 5761 | 3674 | ||||||||||||||||||||||||||||||||||||||||

| S 15 | 3765/1281 | 5393/2909 | 7020/4536 | 8648/6164 | 6172 | 3937 | ||||||||||||||||||||||||||||||||||||||||

| S 16 | 5101/2452 | 6728/4079 | 8356/5707 | 6584 | 4199 | |||||||||||||||||||||||||||||||||||||||||

Double Acting Output Torque

| Pressure | 3bar | 4bar | 4.5bar | 5bar | 5.5bar | 6bar | 7bar | 8bar | ||||||||||||||||||||||||||||||||||||||

| Type | 2.5bar | |||||||||||||||||||||||||||||||||||||||||||||

| HPA050DA | 8.3 | 10 | 13.3 | 15 | 16.6 | 18.3 | 19.9 | 23.3 | 26.6 | |||||||||||||||||||||||||||||||||||||

| HPA063DA | 14.7 | 17.6 | 23.5 | 26.4 | 29.3 | 32.2 | 35.2 | 41 | 46.9 | |||||||||||||||||||||||||||||||||||||

| HPA075DA | 29.1 | 34.9 | 46.5 | 52.4 | 58.2 | 64 | 69.8 | 81.4 | 93.1 | |||||||||||||||||||||||||||||||||||||

| HPA088DA | 45.8 | 54.9 | 73.2 | 82.4 | 91.5 | 100.7 | 109.8 | 128.1 | 146.6 | |||||||||||||||||||||||||||||||||||||

| HPA100DA | 66.5 | 79.8 | 106 | 120 | 133 | 146 | 160 | 186 | 213 | |||||||||||||||||||||||||||||||||||||

| HPA115DA | 107 | 129 | 172 | 193 | 215 | 236 | 258 | 301 | 344 | |||||||||||||||||||||||||||||||||||||

| HPA125DA | 138 | 166 | 222 | 249 | 277 | 305 | 332 | 388 | 443 | |||||||||||||||||||||||||||||||||||||

| HPA145DA | 217 | 261 | 348 | 391 | 435 | 478 | 522 | 609 | 696 | |||||||||||||||||||||||||||||||||||||

| HPA160DA | 284 | 340 | 454 | 511 | 567 | 624 | 681 | 794 | 908 | |||||||||||||||||||||||||||||||||||||

| HPA190DA | 420 | 638 | 851 | 958 | 1064 | 1170 | 1277 | 1490 | 1702 | |||||||||||||||||||||||||||||||||||||

| HPA210DA | 532 | 798 | 1064 | 1197 | 1330 | 1463 | 1596 | 1862 | 2128 | |||||||||||||||||||||||||||||||||||||

| HPA240DA | 769 | 1154 | 1539 | 1731 | 1924 | 2116 | 2308 | 2693 | 3078 | |||||||||||||||||||||||||||||||||||||

| HPA270DA | 1170 | 1750 | 2339 | 2632 | 2924 | 3216 | 3509 | 4094 | 4679 | |||||||||||||||||||||||||||||||||||||

| HPA300DA | 1526 | 2289 | 3052 | 3434 | 3815 | 4197 | 4578 | 5341 | 6104 | |||||||||||||||||||||||||||||||||||||

| HPA350DA | 2285 | 3427 | 4570 | 5141 | 5712 | 6283 | 6854 | 7997 | 9139 | |||||||||||||||||||||||||||||||||||||

| HPA400DA | 3256 | 4884 | 6512 | 7326 | 8140 | 8954 | 9768 | 11396 | 13024 | |||||||||||||||||||||||||||||||||||||

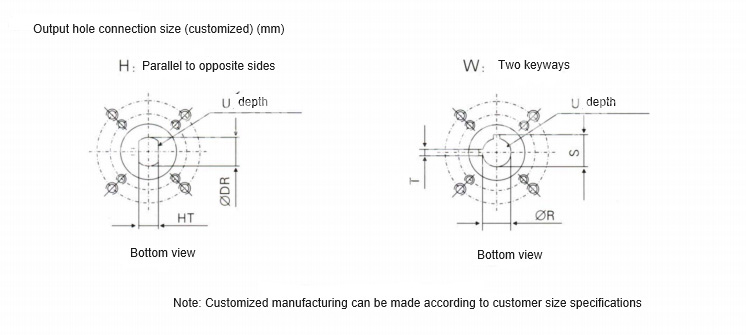

Output Hole Size

| Type | 50 | 63 | 75 | 88 | 100 | 115 | 125 | 145 | 160 | 190 | 210 | 240 | 270 | 300 | ||||||||||||||||||||||||||||||

| HPA(SR)/HPA(DA) | ||||||||||||||||||||||||||||||||||||||||||||

| ΦR | 12.7 | 12.7 | 12.7 | 15.88 | 19.05 | 22.23 | 22.23 | 28.58 | 28.58 | 31.75 | 31.75 | 33.34 | 38.1 | 41.28 | ||||||||||||||||||||||||||||||

| S | 14.2 | 14.2 | 14.2 | 18.4 | 21.6 | 24.8 | 24.8 | 32.1 | 32.1 | 35.3 | 35.3 | 37.4 | 42.4 | 45.3 | ||||||||||||||||||||||||||||||

| T | 3 | 3 | 3 | 5 | 5 | 5 | 5 | 8 | 8 | 8 | 8 | 10 | 10 | 12 | ||||||||||||||||||||||||||||||

| U | 32 | 32 | 32 | 32 | 32 | 45 | 45 | 45 | 45 | 45 | 45 | 51 | 51 | 65 | ||||||||||||||||||||||||||||||

| φDR | 13 | 13 | 13 | 16.1 | 19.2 | 22.4 | 22.4 | 28.8 | 28.8 | 32 | 32 | 33.6 | 38.4 | 41.5 | ||||||||||||||||||||||||||||||

| HT | 10 | 10 | 10 | 12 | 14 | 17 | 17 | 22 | 22 | 24 | 24 | 27 | 27 | 32 | ||||||||||||||||||||||||||||||

Full stroke adjustment limit actuator

The new pneumatic actuator provides special adjustment limit screws at both ends, allowing customers to adjust any angle

within the range of 0 ° -90 °, 0 ° -120 °, or 0 ° -180 ° as needed. Full stroke adjustment can be performed on all series of actuators

External Dimensions

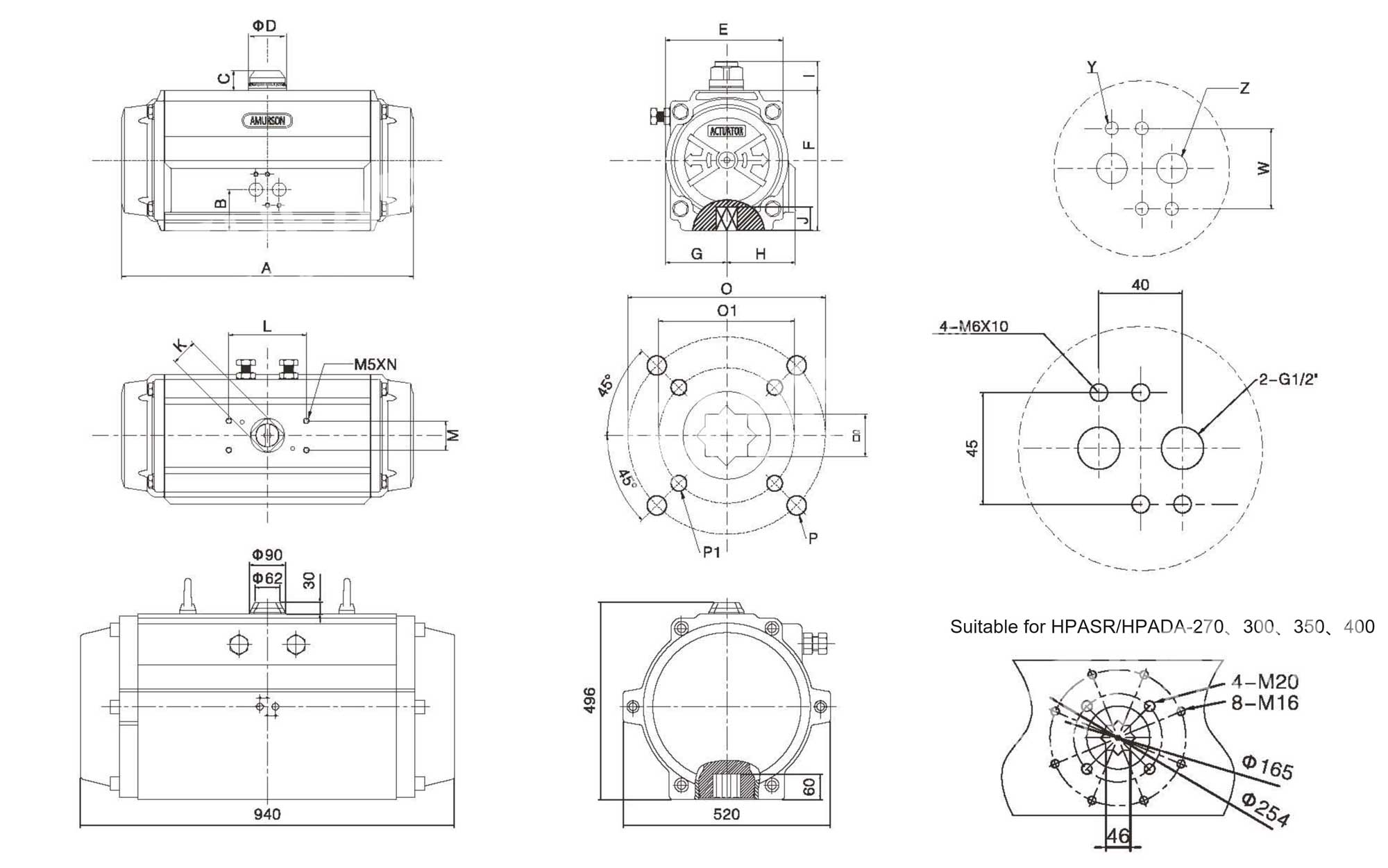

HPA400SR/HPA400DA Dimensional Drawing

| Type | 50 | 63 | 75 | 88 | 100 | 115 | 125 | 145 | 160 | 190 | 210 | 240 | 270 | 300 | 350 | 400 | ||||||||||||||||||||||||||||||

| HPADA/HPASR | ||||||||||||||||||||||||||||||||||||||||||||||

| A | 140.5 | 158.5 | 210.5 | 247.5 | 268.5 | 315 | 345 | 408.5 | 437.5 | 540 | 555 | 602 | 718 | 760 | 920 | 940 | ||||||||||||||||||||||||||||||

| B | 26.5 | 30 | 30.5 | 32.5 | 37.5 | 42.5 | 45 | 47.5 | 52 | 54 | 58 | 66 | 81 | 83 | 97 | 232 | ||||||||||||||||||||||||||||||

| C | 20 | 20 | 20 | 20 | 20 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | ||||||||||||||||||||||||||||||

| D | 40 | 40 | 40 | 40 | 40 | 56 | 56 | 65 | 65 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | ||||||||||||||||||||||||||||||

| E | 59 | 72 | 84.5 | 97.5 | 111 | 127 | 136 | 156.5 | 169 | 190.5 | 213 | 245 | 273 | 312 | 365 | 298 | ||||||||||||||||||||||||||||||

| F | 69 | 85 | 102 | 115 | 127 | 145 | 157 | 177 | 196 | 230 | 250 | 319 | 356 | 380 | 440 | 496 | ||||||||||||||||||||||||||||||

| G | 29 | 36 | 42.5 | 49.5 | 56 | 64 | 69.5 | 80 | 88 | 103 | 113.5 | 130 | 147 | 162 | 190 | 260 | ||||||||||||||||||||||||||||||

| H | 41.5 | 47 | 52 | 56.8 | 67 | 77 | 82 | 91.5 | 99 | 103 | 113.5 | 130 | 147 | 174 | 195 | 260 | ||||||||||||||||||||||||||||||

| I | 14.5 | 14.5 | 14.5 | 14.5 | 14.5 | 24.5 | 24.5 | 24.5 | 24.5 | 24.5 | 24.5 | 30 | 30 | 30 | 30 | 30 | ||||||||||||||||||||||||||||||

| Jmin | 12 | 16 | 16 | 19 | 19 | 24 | 24 | 29 | 29 | 29 | 38 | 50 | 50 | 50 | 50 | 50 | ||||||||||||||||||||||||||||||

| K | 11 | 11 | 17 | 17 | 17 | 27 | 27 | 27 | 27 | 36 | 36 | 46 | 46 | 46 | 46 | 46 | ||||||||||||||||||||||||||||||

| L | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 130 | 130 | 130 | 130 | 130 | 130 | 130 | ||||||||||||||||||||||||||||||

| M | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | ||||||||||||||||||||||||||||||

| N | 4 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | ||||||||||||||||||||||||||||||

| 01 | F03 | F05 | F05 | F05 | F07 | F07 | F07 | F10 | F10 | F14 | F14 | F16 | F16 | F16 | F25 | F25 | ||||||||||||||||||||||||||||||

| 0 | 一 | F07 | F07 | F10 | F10 | F10 | F12 | F12 | 一 | 一 | 一 | 一 | 一 | 一 | 一 | |||||||||||||||||||||||||||||||

| P1 | 4-M6 | 4-M6 | 4-M6 | 4-M6 | 4-M8 | 4-M8 | 4-M8 | 4-M10 | 4-M10 | 4-M16 | 4-M16 | 4-M20 | 4-M20 | 4-M20 | 8-M20 | 8-M20 | ||||||||||||||||||||||||||||||

| P | 一 | 一 | 4-M8 | 4-M8 | 4-M10 | 4-M10 | 4-M10 | 4-M12 | 4-M12 | 一 | 一 | 一 | 一 | 一 | 8-M16 | 8-M16 | ||||||||||||||||||||||||||||||

| □Q | 11 | 14 | 14 | 17 | 17 | 22 | 22 | 27 | 27 | 27 | 36 | 46 | 46 | 46 | 46 | 46 | ||||||||||||||||||||||||||||||

| V | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | ||||||||||||||||||||||||||||||

| W | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | ||||||||||||||||||||||||||||||

| Y | M58 | M5x8 | M5×8 | M5×8 | M5×8 | M5×8 | M5×8 | M5×8 | M5×8 | M5×8 | M5×8 | M5×8 | M5×8 | M5×8 | M5×8 | M5×8 | ||||||||||||||||||||||||||||||

| Z | 1/4° | 1/4" | 1/4" | 1/4" | 1/4" | 1/4" | 1/4" | 1/4" | 1/4" | 1/4 | 1/4" | 1/4° | 1/2' | 1/2' | 1/2" | 1/2" | ||||||||||||||||||||||||||||||